2) superheat

过热

1.

Safety Analysis of the Stability of the Tubes of a Steam Gas Superheated Furnace;

蒸汽过热炉炉管稳定性安全分析

2.

Further analysis of the effect on the refrigeration coefficient with the superheat of the refrigeration cycle;

制冷循环的过热对制冷系数影响的探讨

3.

This paper draws the systematical sketch for diagnosis and disposing of the shearer hydraulic system superheat phenomena so that the trouble will be found out and disposed as quickly as possible.

笔者按采煤机液压系统发生过热故障的相似性或检查故障时的难易程度排列,制作了采煤机液压系统过热现象的诊断及处理方法示意图,据此可迅速找到故障原因及处理办法。

3) superheating

过热

1.

Study on superheating on surface-free bulk crystals;

非自由表面大块晶体过热的初探

2.

Melting and Superheating of Ag at High Heating Rate;

金属银在高升温速率下的熔化和过热行为

3.

Ag melting and superheating at high heating rate;

升温速率对金属熔化和过热的影响

4) over heat

过热

1.

The results show that the fracture is caused by the heating temperature controlled improperly during forging which leads to the over heat, and the heating temperature is too low in the following quenching process that leads to the bad solution strengthening.

即叶轮断裂是由于锻造加热时温度控制不好导致过热,在随后的淬火工序中又因加热温度过低,组织固溶强化效果差等综合原因所致。

2.

Analysis shows that the primary cause to the roll failure is the over heat of the roll and therefore some counter measures have been put foreword to prevent against the trouble of roll fracture.

用于中厚板轧机和热连轧轧机的高铬、高镍铬复合铸铁轧辊在使用中相继发生断辊事故 ,断辊事故的原因是由于轧辊过热所致 ,提出防止断辊事故的具体对策和改进措施。

3.

,by comprehensive analyzing,finds out the direct reason is foreign body dropped into the tube in the process of boiler installation and engendered the blockage,the working substance is not moving on smoothly,the tube cannot get the sufficient cooling when the boiler running,the tube wall long-term over heat operates,caused the tube explode and leak.

针对宁夏中宁发电有限公司#2锅炉运行仅3000小时左右,高温再热器管在同一部位爆管2次进行综合分析,找出爆管的直接原因是由于锅炉安装过程中管内不慎落入异物,造成阻塞、工质流动不畅,锅炉运行时管子得不到充分冷却,管壁超温而引起长期过热爆漏。

5) Overheating

过热

1.

It was found that the overheating of material during heat treatment led to coarse crystalline grains.

结果表明:由于热加工时加热温度控制不当,使泵体过热而导致晶粒长大,强度下降。

2.

The results show that the wheel hub cracking during radial impact testing was caused by excessive content of magnesium in the alloy as well as the overheating of the alloy during the solution process.

结果表明 ,轮毂在径向冲击检测时开裂的主要原因是镁含量偏高 ,以及热处理加热温度高造成组织过热所致。

6) Overheat

过热

1.

The Research on the Overheat of H13 Hot Die Steel Forging;

H13热模钢锻材过热的研究

2.

Overheat Fault of Tap-Changer Contact and Its Diagnosis;

分接开关触头过热性故障及其诊断

3.

Fault Tree Analysis on Overheat of Vehicle Engine;

车用发动机过热故障树分析

参考词条

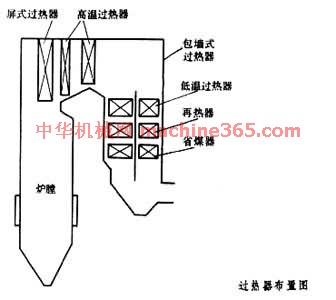

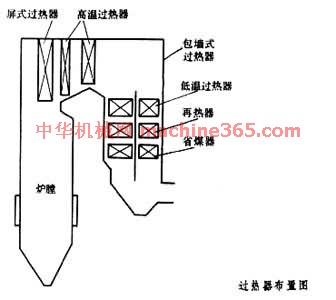

补充资料:动力机械:过热器

锅炉中将蒸汽从饱和温度进一步加热至过热温度的部件﹐又称蒸汽过热器。大部分工业锅炉不装设过热器﹐因为许多工业生产流程和生活设施只需要饱和蒸汽。在电站﹑机车和船用锅炉中﹐为了提高整个蒸汽动力装置的循环热效率﹐一般都装有过热器。采用过热蒸汽可以减少汽轮机排汽中的含水率。过热蒸汽温度的高低取决于锅炉的压力﹑蒸发量﹑钢材的耐高温性能以及燃料与钢材的比价等因素﹐对电站锅炉来说﹐4兆帕的锅炉一般为450℃左右﹔10兆帕以上的锅炉为540~570℃。少数电站锅炉也有采用更高过热汽温的(甚至可达650℃)。

类型和特点 过热器按传热方式可分为对流式﹑辐射式和半辐射式﹔按结构特点可分为蛇形管式﹑屏式﹑墙式和包墙式。它们都由若干根并联管子和进出口集箱组成。管子的外径一般为30~60毫米。对流式过热器最为常用﹐采用蛇形管式。它具有比较密集的管组﹐布置在 450~1000℃烟气温度的烟道中﹐受烟气的横向和纵向冲刷。烟气主要以对流的方式将热量传递给管子﹐也有一部分辐射吸热量。屏式过热器由多片管屏组成﹐布置在炉膛内上部或出口处﹐属于辐射或半辐射式过热器。前者吸收炉膛火焰的辐射热﹐后者还吸收一部分对流热量。在10兆帕以上的电站锅炉中﹐一般都兼用屏式和蛇形管式两种过热器﹐以增加吸热量。敷在炉膛内壁上的墙式过热器为辐射式过热器﹐较少采用。包墙式过热器用在大容量的电站锅炉中构成炉顶和对流烟道的壁面﹐外面敷以绝热材料组成轻型炉墙。图 过热器布置图  为几种过热器的布置。装有过热器的小容量工业锅炉一般只用单级管组的对流式过热器即能满足要求。

为几种过热器的布置。装有过热器的小容量工业锅炉一般只用单级管组的对流式过热器即能满足要求。

性能 锅炉运行工况的变化﹐例如负荷高低﹑燃料变化﹑燃烧工况变动等﹐都对过热器出口汽温有影响﹐所以在电站锅炉中都有调节锅炉出口汽温使其稳定在规定值的手段。常用手段有﹕ 用喷水式或表面式减温器直接调节汽温﹔ 用摆动燃烧器改变炉膛出口烟气温度﹔ 用烟气再循环调节过热器吸热量(见锅炉汽温调节)。锅炉负荷升高时﹐对流式过热器的进出口蒸汽温度升高值增大﹐辐射式过热器的温度升高值减小。若将对流式﹑辐射式和半辐射式过热器合理组合配置﹐则可在负荷﹑燃烧工况等变化时使出口汽温变化较小。过热器管组中各并联管子的吸热量和蒸汽流量在运行中都会有差别。为避免个别管子中温度过高﹐在大型锅炉中把过热器分成若干管组﹐用炉外的集箱对各管组蒸汽进行混合并用导汽管使各管组换位﹐以避免各管间出现过大的温度差。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

为几种过热器的布置。装有过热器的小容量工业锅炉一般只用单级管组的对流式过热器即能满足要求。

为几种过热器的布置。装有过热器的小容量工业锅炉一般只用单级管组的对流式过热器即能满足要求。