1) PGL3 carrier

pGL3载体

1.

METHODS: The hTERT promoter and TK gene were cloned, andwhich was connected to the PGL3 carrier after enzyme digestion, toconstruct the hTERTp/PGL3、TK/PGL3、hTERTp/TK/PGL3 recombinantcarriers, and then to construct the CMV/TK/PGL3 recombinant carrierswith the similar method and regard CMV a.

方法:克隆hTERT启动子及TK基因,酶切后连接到pGL3载体上,构建hTERTp/pGL3,TK/pGL3,hTERTp/TK/pGL3重组载体。

2) pGL3-Basic vector

pGL3-Basic载体

1.

Then P4 promoter gene fragment was inserted into the KpnI-HindⅢsite of pGL3-Basic vector,to construct pGL3-Basic eukaryotic expression vector bearing P4 promoter gene,pGL3-P4,which was further confirmed by double enzyme digestion and DNA sequencing.

成功克隆IGF-ⅡP4启动子基因,并构建P4启动子的pGL3-Basic载体。

2.

After three promoter segments with different lengths were amplified by PCR amplification,and then the products were identified by DNA sequencing,four promotor segments were inserted into pGL3-Basic vectors.

方法运用在线软件Cister对CCDC72基因5’端2000bp进行启动子特征分析;以人毛乳头细胞基因组DNA为模板进行PCR扩增目并进行测序鉴定,再以扩增产物为模板PCR得到不同长度的启动子片段,并测序,将获得启动子片段插入pGL3-Basic载体。

3) pGL3-p21p vector

pGL3-p21p载体

4) promoter-pGL3-Basic-GFP expressed vector

pGL3-Basic-GFP表达载体

5) pGL3-basic plasmid

pGL3-basic真核表达载体

1.

Methods Different lengths CDA1P were amplified by PCR using mouse liver genomic as template and cloned into BglⅡ digested pGL3-basic plasmid to produce recombinant plasmid pGL3-basicmCDA1P,then they were transfected into Lewis lung cell line(LLC) and RAW 264.

方法:以小鼠肝脏的全基因序列为模板,用PCR方法获得不同长度的目的片段,连接到pGL3-basic真核表达载体(pGL3-basic-mCDA1P),纯化pGL3-basic mCDA1P质粒后,瞬时转染到Leuwis肺癌细胞和单核巨噬细胞(RAW264。

6) luciferase reporter vector

萤光素酶报告载体pGL3

1.

Aim:To construct a luciferase reporter vector with neomycin resistance.

方法:设计扩增新霉素抗性基因neo,克隆入萤光素酶报告载体pGL3,得到pGL3-neo。

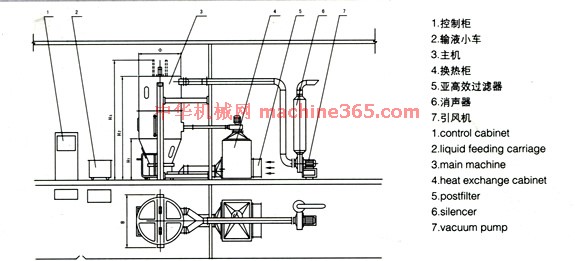

补充资料:PGL系列喷雾干燥制粒机

特点:

集喷雾干燥/流化制粒于一体,实现液态物料一步法制粒。

采用喷雾工艺,特别适用微辅料,热敏性物料,功效比FL沸腾制粒机高1~2倍速。

产品终水份可达0.1%,配备返粉装置,成粒率≥95%,可制0.2-2mm。

改进设计的内混式多流体雾化器可处理浸膏比重达1.3g/cm3。

原理:

将一定的粉体物料放入流化床内作为晶种,液态物料经泵送至喷嘴雾化器。首先与喷雾用高温空气瞬间除去部分水分;残余水分则在底部流化床低温干燥完成;并同时成粒。

应用:

制药工业:片剂、冲剂、胶囊剂颗粒;低糖、无糖的中成药颗粒。

食品:可可、咖啡、奶粉、颗粒果汁、调味品等。

其它行业:农药、饲料、化肥、颜料、染料等。

安装示意图:

技术参数:

项目 | 单位机型 | PGL-3 | PGL-5 | PGL-10 | PGL-20 | PGL-30 | PGL-80 | PGL-120 | |

流浸膏 | 最小 | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

最大 | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

沸腾能力 | 最小 | kg/批 | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

最大 | kg/批 | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

液体比重 | kg/h | ≤1.30 | |||||||

原料容器量 | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

容器直径 | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

引风机功率 | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

辅风机功率 | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

蒸气 | 耗量 | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

压力 | Mpa | 0.4.-0.06 | |||||||

电热型功率 | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

压缩空气 | 耗量 | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

压力 | Mpa | 0.40-0.60 | |||||||

作业温度 | ℃ | 室温-160℃自动调节 | |||||||

产品水分 | % | ≥0.2% | |||||||

物料收得率 | % | ≥99% | |||||||

设备噪音 | dB | <77 | |||||||

主机尺寸 | ø | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条

专业词汇(按中图法分类)

专业词汇(按中图法分类)