2) thin-walled part

薄壁零件

1.

Based on it,a dynamic force model for milling process of thin-walled parts is established using a two-freedom elastic-damping system by considering the dynamic characteristics of the tool subsystem and the workpiece subsystem.

在此基础上,采用两自由度弹性-阻尼系统,建立了适合薄壁零件的综合考虑刀具子系统和工件子系统动态特性的动态铣削力模型。

3) Thin-wall parts

薄壁零件

1.

This paper analyses the relation between the cutting force and cutting depth in the course of belt grinding,builds the mathematics model of optimum cutting parameter to improve efficiency and intensity,and proposes the processing method for controlling griding precision of rotary thin-wall parts.

通过实验分析了带轮磨削过程中切削力和切削深度之间的关系,从提高切削效率和强度出发,选择优化切削参数,建立了切削参数数学模型;提出了控制回转形薄壁零件磨削精度的加工方

2.

As to the problem of cutting chatter found in the course of thin-wall parts milling,a theoretical model with regard to milling charter was established to conduct modal analysis experiments and milling experiments with a view to obtaining dynamic performance parameters of the system and milling force coefficient.

针对薄壁零件在铣削加工过程中存在的切削颤振问题,建立了铣削颤振理论模型,进行模态分析试验和铣削加工试验,获取系统动态性能参数和铣削力系数。

3.

The causes of deformation,size out-of-tolerance and collidings of the annular thin-wall parts produced by copper alloy extrusion materials are analyzed,and through production experiment,the reasonable process has be determined,which can reduce the production cost and improve product quality.

分析了利用铜合金挤压材加工环状薄壁零件生产过程中产生变形、尺寸超差、磕碰的原因,并通过生产实验确定了合理的加工工艺路线,降低了生产成本,提高了产品质量。

4) thin-walled component

薄壁零件

1.

To investigate the vibration principle in machining thin-walled components, a dynamic model for end milling of flexible structures is built based on considering the variations in the dynamic chip thickness and the differences between up-milling and down-milling.

为研究薄壁零件加工的振动机理,本文在考虑动态切削厚度的变化以及顺铣和逆铣之间差别的基础上,建立了一个薄壁零件立铣的力学模型,并用两个铣削实例加以验证。

5) thin wall part

薄壁零件

1.

For high speed cutting technology is widely used in machinary, this article introduces the characteristics of process planning and programming method of high speed milling with an example of aluminium alloy thin wall part.

针对高速切削技术在切削加工领域的广阔应用前景,以铝合金薄壁零件的加工为例,介绍了高速铣削 加工的工艺特点及编程方法。

2.

Taking NC turning for instance,the paper gives specific solutions on account of the existing factors of accuracy in machining thin wall part.

薄壁零件在工业生产中得到广泛应用,但因薄壁零件刚性差、强度弱,在加工中极易变形,不易保证零件的加工质量。

3.

These methods were proved to be effective in increasing the machining quality of the thin wall parts.

薄壁零件在工业生产中得到广泛的应用,但因薄壁零件刚性差,强度弱,在加工中极易变形,不易保证零件的加工质量。

6) thin wall parts

薄壁零件

1.

By laser engineering net shaping (LENS) Co- based alloy powder for multi-layer test was melted on a steel substrate,and the thin wall parts 2~20mm with smooth surface and accurate size was obtained.

利用激光近成形技术 ,采用钴基合金粉末在金属零件表面进行单道多层熔覆成形试验 ,获得具有良好外形和尺寸精度 2~ 2 0mm的薄壁零件。

2.

The process rigidity character of low rigidity thin wall parts was ana lyzed.

分析了低刚度薄壁零件的工艺刚度特征及其加工过程的受力变形特性 ,提出了实现低刚度薄壁零件精密加工的技术途径。

补充资料:如何提高薄壁零件的加工精度

因为具有重量轻、节约材料、结构紧凑等特点,薄壁零件已日益广泛地应用在各工业部门。但薄壁零件的加工是比较棘手的,原因是薄壁零件刚性差、强度弱,在加工中极容易变形,不易保证零件的加工质量。如何提高薄壁零件的加工精度将是业界越来越关心的话题。

薄壁零件的加工问题,一直是较难解决的。薄壁件目前一般采用数控车削的方式进行加工,为此要对工件的装夹、刀具几何参数、程序的编制等方面进行试验,从而有效地克服了薄壁零件加工过程中出现的变形,保证加工精度。影响薄壁零件加工精度的因素有很多,但归纳直来主要有以下三个方面:

(1)受力变形

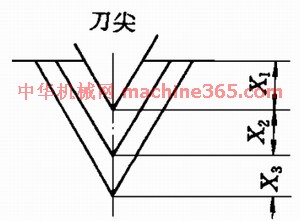

因工件壁薄,在夹紧力的作用下容易产生变形,从而影响工件的尺寸精度和形状精度,如图1所示。

(2)受热变形

因工件较薄,切削热会引起工件热变形,使工件尺寸难于控制。

(3)振动变形

在切削力(特别是径向切削力)的作用下,很容易产生振动和变形,影响工件的尺寸精度、形状、位置精度和表面粗糙度。

图1 夹紧力的影响

既然影响薄壁件加工精的因素找到了,那么我们将如何提高薄壁零件的加工精度呢?接下来笔者将通过具体实例来介绍提高薄壁件加工精度和效率的措施。

图2所示的薄壁零件,是我校用数控车床对外加工产品中难度较大的零件。采用的设备是配备了广州数控系统GSK980T的数控车床。为了提高产品的合格率,我们从工件的装夹、刀具几何参数、程序的编制等方面进行综合考虑,实践证明,有效提高了零件的精度,保证了产品的质量。

图2 示例零件

1. 工件特点分析

从零件图样要求及材料来看,加工此零件的难度主要有两点:

(1)因为是薄壁零件,螺纹部分厚度仅有4mm,材料为45号钢,而且批量较大,既要考虑如何保证工件在加工时的定位精度,又要考虑装夹方便、可靠。通常的车削都是用三爪卡盘夹持外圆或撑内孔的装夹方法来加工,但此零件较薄,车削受力点与加紧力作用点相对较远,而且还需车削M24螺纹,受力很大,刚性不足,容易引起晃动,因此要充分考虑如何装夹定位的问题。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条