1) weld arc length

焊接弧长

1.

Backing weld procedure technique of all position narrow gap and thick walled pipe welding is developed about all position single pass welding section analysis,wire feeding behavior , weld arc length , welding current analysis,procedure and joint test.

从单焊道全位置区段、送丝行为、焊接弧长 (电压 )、电流行为分析、工艺试验和接头检验等几方面介绍管道全位置打底焊工艺特点 ,其研究成果对全位置焊接机的制造和调试具有普遍指导意义。

2) submerged arc welding

埋弧焊接

1.

Effect of arc offset on the quality of submerged arc welding and improving measures of the welding technology;

弧偏吹对埋弧焊接质量的影响和焊接工艺改进措施

2.

Based on Buck DC/DC converter,an arc stability controller was designed for submerged arc welding(SAW).

基于Buck DC/DC变换器,设计了埋弧焊接(Submerged arc welding,SAW)过程的稳弧控制器。

3) welding arc

焊接电弧

1.

Study on the effect of the ZA alloy TIG flux on the weld formation and welding arc;

ChinZA合金TIG焊剂对焊接电弧及焊缝成型的影响

2.

Variable polarity TIG welding arc dynamic analyzer;

变极性TIG焊接电弧多信息测试分析系统

3.

Spectral space character of welding arc and its applications;

焊接电弧光谱的空间特征及应用研究

4) argon arc welding

氩弧焊接

1.

The friction stir welding of 2mm thick 01420 Al-Li alloy was conducted,the microstructures,qualities of joining,and mechanical properties of the joints as well as the influences of welding parameters on the alloy were investigated,meanwhile comparing the mechanical properties with that of the joint welded by argon arc welding.

对2 mm厚的01420铝锂合金薄板实现了搅拌摩擦焊接(FSW),分析焊接接头的微观组织形态,研究焊接工艺参数对搅拌摩擦焊接接头成型和接头性能的影响,并与氩弧焊接接头性能相比较。

2.

It also gave the reason of the crack which is produced in the splice welded seam, and madea clear summary of the practice in controlling the technical process of argon arc welding.

介绍了抛物面天线整体旋压成型的工艺过程,针对旋压过程铝板拼接焊缝开裂的原因进行了初步分析,并对氩弧焊接工艺控制过程的经验进行了总结。

3.

The technology of microcomputer monitor system which applied in argon arc welding procedure of the manufacture of automatically activated primary Zn AgO batteries was introduced.

介绍了由微机和监视技术组成的监控装置在自动激活一次锌氧化银电池制造工艺中氩弧焊接技术上的应用,着重阐述该系统中的监控装置、焊接装置及I/O接口控制电路。

5) arc welding

电弧焊接

1.

A comprehensive discussion is given to arc welding technologies easy to complete semi_automatic and automatic welding and the application of arc welding in automatic industry is analysed based on practical examples.

说明了应用自保护管状焊条焊接和特种气体保护焊接技术这种电弧焊接方法的意义及发展前景。

6) argon-arc welded

氩弧焊接

1.

By using ANSYS,the temperature field of tube to tube sheet argon-arc welded joint which consisting of tantalum(Ta)tube and Ta/16MnR clad sheet was simulated.

利用ANSYS软件对用钽制换热管、Ta/16MnR制管板的管板式换热器中氩弧焊接接头进行了数值模拟,得到了4种尺寸组合焊接接头的温度场数值模拟结果。

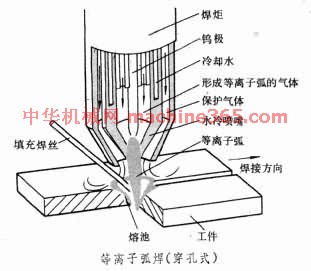

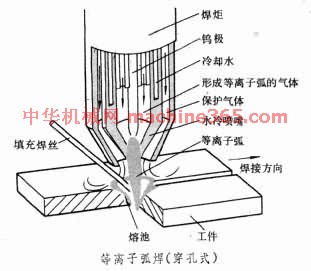

补充资料:焊接:等离子弧焊

利用等离子弧作为热源的焊接方法(见图 等离子弧焊(穿孔式)  )。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条