1) fitter practice

钳工实习

1.

Summarise the experience of the practice teaching and produce practice of the year, drawing up the effective basic step and teaching principle of fitter practice teaching.

总结多年实习教学和生产实践的经验,制定出行之有效的钳工实习教学的基本步骤和教学原则。

2) A Tentative Study on the Practice Teaching of the Benchwork

钳工实习教学初探

3) benchwork practice

钳工实训

1.

For benchwork practice,the teacher,in accordance with "Guiding Text Approach",will leave students the questions or tasks in the form of guiding questions.

在钳工实训中,采用"引导文教学法",对钳工实习教学方法进行积极的探索和实践。

4) hands-on metal fitter practice

钳工实践

1.

The paper studies the college hands-on metal fitter practice and teaching program, discussing its important position in the mechanical engineering profession and its contents, methods and management, with a purpose to strengthen the combination between theory and practice for greater competence and effect.

通过对高校金工实训中的钳工实践教学、钳工实践与学科的关系、教学方法、教学内容的组织和教学管理等方面的研究,旨在实践过程中,加强理论与实践的有机联系,提高教学效果,并确定钳工实践教学在整个金工实训中的重要位置。

5) lathe work practice

车工实习

1.

Infiltrative teaching of professional knowledge in the lathe work practice;

专业知识在车工实习中的渗透教学

2.

This article discusses the teaching characteristics of lathe work practice elective course,pnts forward the focal points,the test its way and standards and probes into the teaching of lathe work practice elective course.

本文通过对高职车工实习选修课教学特点的总结和分析,提出车工实习选修课教学的重点,改进了实习成绩考核办法和标准,对车工实习选修课教学进行了有益的探索。

3.

This paper expounds the teaching methods,and puts forward some suggestions to improve the quality of lathe work practices.

本文对车工实习的教学方法进行了探讨,提出了的改进实习质量的若干建议与设想。

6) metalworking practice

金工实习

1.

Elementary discussion on cultivating and training innovative thinking during metalworking practice;

浅谈创新思维在金工实习中的培养与训练

2.

Deepen the teaching reform of metalworking practice under the credit system;

深化学分制下的金工实习教学改革

3.

Application of "diversity teaching method" in teaching of metalworking practice;

“差异教学法”在金工实习教学中的应用

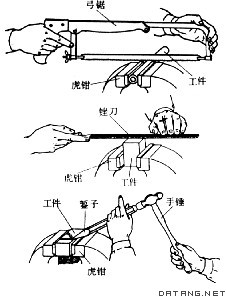

补充资料:钳工

| 钳工 bench work 机械制造中最古老的金属加工技术,切削加工、机械装配和修理作业中的手工作业。有时也把从事该手工作业的人称为钳工。因常在钳工台上用虎钳夹持工件操作而得名。钻孔有时也算钳工的一部分。钳工作业大部分已机械化、自动化,但在单件小批生产、装配、维修等场合仍广泛应用。 钳工在机械制造中的作用是:生产前的准备;单件小批生产中的部分加工;生产工具的调整;设备的维修和产品的装配等。作业一般分为划线、锯割、錾削、锉削、刮削、钻孔、铰孔、攻丝、套丝、研磨、矫正、弯曲、铆接和装配等。钳工按照专业性质分为普通钳工、划线钳工、模具钳工、刮研钳工、装配钳工、机修钳工和管子钳工等。作业的质量和效率在很大程度上依赖于操作者的技艺和熟练程度。

|

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条