1) friction stir welding

摩擦搅拌焊

1.

New welding technology of aluminium alloy which is newly researched throughout the world is summarized in the paper,such as laser welding,laser-arc hybrid welding and friction stir welding.

详细介绍了近年来国内外出现的铝合金焊接新技术(激光焊、激光-电弧复合焊以及摩擦搅拌焊)的原理、工艺特点以及在汽车制造中的应用。

2.

So it is very important to study the friction stir welding techno.

摩擦搅拌焊是一种用于低熔点铝合金板材的固态焊接方法,用该方法可以焊接通常熔化焊方法难于焊接的铝合金材料。

3.

The stress cracking corrosion performance of the specimen prepared by friction stir welding is better than by metal inert gas welding.

结果表明:外加阴极极化使7A52铝合金的应力腐蚀指数增大,应力腐蚀敏感性呈增大趋势;摩擦搅拌焊件应力腐蚀性能优于熔焊件。

2) friction stir weld

搅拌摩擦焊

1.

Investigation on defect dynamic echo waveform of friction stir welding;

搅拌摩擦焊焊缝缺陷的超声波动态波形分析

2.

The metal flowing behavior in weld zone has a great influence on the welds mechanical performance in friction stir welding.

搅拌摩擦焊中焊缝材料的流动对焊件性能有很大影响。

3.

The friction stir welding (FSW) of 5 mm thickness plates of 1060 Al/3003 Al was carried out.

搅拌摩擦焊中,材料的流动状态对焊件性能有很大影响。

3) friction stir welding

搅拌摩擦焊

1.

Influences of friction stir welding parameters on microstructure and mechanical properties of dissimilar magnesium alloys joint;

搅拌摩擦焊工艺参数对异种镁合金接头组织和性能的影响

2.

Development and application of friction stir welding;

搅拌摩擦焊接技术的研究进展和应用

3.

Analysis of Defects in Friction Stir Welding of Aluminum Alloy;

铝合金搅拌摩擦焊焊接过程缺陷分析

4) friction stir welding(FSW)

搅拌摩擦焊

1.

This paper introduces the principle and characteristics of friction stir welding(FSW),the materials and design of shoulder and pin of FSW,the fix of welded workpiece,the application of simulation and modeling techniques,as well as the feasibility of its applications to naval weaponry such as advanced amphibious assault vehicle(AAAV) and ships.

概述了搅拌摩擦焊的工作原理及其特性,搅拌摩擦头材料与设计,被焊接工件的固定,模拟和模型技术的应用,以及它在船舶和两栖突击车上的应用可行性。

2.

The influence of friction stir welding(FSW) process on magnesium alloy's mechanical properties is analyxed through tensile tests and bend tests.

采用不同搅拌摩擦焊工艺焊接镁合金,通过拉伸、三点弯曲试验分析了工艺参数对焊缝机械性能的影响。

3.

6M NaCl solution,by static weight loss experiment(gravimetric test) and potentiodynamic polarization curve and electrochemical impedance spectroscopy(EIS),the electrochemical corrosion behaviors of friction stir welding(FSW) dissimilar weld of 5083 and 6082 aluminum alloy and two parent materials were comparatively investigated.

首先,对铝合金5083-6082搅拌摩擦焊(FSW)焊缝与5083母材、6082母材的金相组织进行了研究,结果表明,焊缝的组织与两种母材相比,其晶粒明显细化。

5) friction-stir welding

搅拌摩擦焊

1.

Investigation of the technology of friction-stir welding for dissimilar materials of T2 copper to H62 brass;

T2紫铜与H62黄铜异种材料间的搅拌摩擦焊工艺研究

2.

Wearing mechanism of tools in friction-stir welding joint of stainless steel;

不锈钢搅拌摩擦焊摩擦头磨损机理研究

3.

Microstructures and mechanical properties of friction-stir welding joint of 7A09 aluminium alloy thick-sheet;

7A09铝合金厚板搅拌摩擦焊接头显微组织与性能研究

6) FSW

搅拌摩擦焊

1.

Analysis and comparison of FSW temperature field simulation of plates 3 mm-LY12 and 10 mm-LF2;

3mmLY12与10mmLF2搅拌摩擦焊温度场模拟分析比较

2.

High-effective,solid-phase new welding technology——FSW;

高效、固相焊接新技术——搅拌摩擦焊

3.

Influences of FSW parameters on mechanical properties of LF6/ LD10 aluminum alloy;

LF6/LD10铝合金搅拌摩擦焊工艺参数对接头性能的影响

补充资料:焊接:摩擦焊

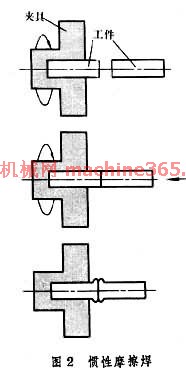

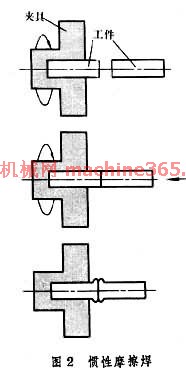

利用工件端面相互摩擦產生的热量使之达到塑性状态﹐然后顶锻完成焊接的方法。车削工件时切屑往往牢牢地黏在刀头上﹐轴与轴瓦之间润滑不良时也会產生局部焊合﹐摩擦焊就是从这些现象出发而发明的。摩擦焊可分为连续驱动摩擦焊和惯性摩擦焊两种。①连续驱动摩擦焊﹕由电动机带动一个工件旋转﹐同时把另一工件压向旋转工件﹐使其接触面相互摩擦產生热量和一定塑性变形﹐然后停止旋转﹐同时施加顶锻压力完成焊接(图1 连续驱动摩擦焊 )。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊 )。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊 )。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条