1) brake and planetary group

制动和行星传动组

2) Combined planetary transmission

组合式行星传动

3) planetary group

行星传动组件

4) planetary gear transmission

行星传动

1.

Comparing many types of transmission,this paper chooses the multiple-level planetary gear transmission to meet the transmission ratio conditions.

首先分析了增速机构设计在履带车辆电磁悬挂设计中的作用,通过选择增速机构的传动方案,得到了满足传动比条件的多级行星传动。

2.

The relation between the radial deformation of the central internal gear in planetary gear transmission and the number of planet gears is derived in this paper.

导出了行星传动中的内啮合中心轮齿圈径向变形与行星轮数目之间的关系,并指出:从提高内啮合中心轮齿圈的柔度出发,行星轮数目应选择荐用范围的下限。

3.

In this paper, the main constraints for the designing of NN type of involute planetary gear transmission are discussed, a concise and practical method for determining the addendum modification coefficients is proposed and some appropriate parameters are provided.

对NN型行星传动的主要限制条件进行了讨论,提供了一种简明实用的变位系数确定方法,推荐了参数选用

5) planetary transmission

行星传动

1.

The Fuzzy Optimization of Multi-objective For the Planetary Transmission Based On The Genetic Algorithm;

基于遗传算法的行星传动多目标模糊优化

2.

Research on the Gear Geometry of Cycloid Enveloping Planetary Transmission;

摆线包络行星传动啮合理论研究

3.

In order to provide the reference to design eccentric wheel handspike planetary transmission,two contact bodies(eccentric wheel and the roller of movable tooth) have been regarded as the perfect elasticity and not to count the dynamic effect of load.

为给偏心轮推杆行星传动的设计提供参考,将偏心轮与活齿内滚柱两接触体视为完全弹性且不计载荷的动力效应,在考虑摩擦的前提下,对偏心轮与内滚柱接触的主应力、最大剪应力、最大八面体剪应力、最大正交剪应力进行了分析和计算。

6) epicyclic transmission

行星传动

1.

The principle of transmission,basic structure,transmission ratio,meshing parameters and transmission efficiency of this kind of epicyclic transmission were discussed and analyzed in this paper.

提出了一种具有实用价值的外齿轮内平动式的新型少齿差行星传动。

2.

In this paper, the characteristics and function of a new model of epicyclic transmission-corn distribution mechanism are described, and the calculation of the transmission ratio is performed.

论述了一种新型行星传动──排粮机构的特点、功能及其传动比计算。

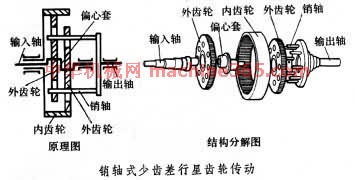

补充资料:传动:少齿差行星齿轮传动

由一对齿数相差很少的内嚙合齿轮和输出机构组成的行星齿轮传动。通常齿数差为1~4。外齿轮通过轴承和偏心套装在减速器的输入轴上(见图 销轴式少齿差行星齿轮传动  )。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

)。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条