1) abrasive cloth

研磨布

2) optical-coated abrasive

光学研磨材料(研磨布纸)

3) grinding

研磨

1.

Fractal model for particle-size distribution of coal grinding;

基于分形方法的煤炭研磨颗粒粒度分布模型

2.

Preparation of γ-Fe_2O_3 Nanoparticles by Solid(wet)-phase Grinding;

γ-Fe_2O_3纳米粒子的(湿)固相研磨法制备研究

3.

The grinding materials and technology for stainless steel;

不锈钢研磨材料及研磨工艺

4) Lapping

研磨

1.

Rapid detection of subsurface damage of optical materials in lapping process and its influence regularity;

光学材料研磨亚表面损伤的快速检测及其影响规律

2.

Research on high speed lapping paraboloid workpiece based on bending and forming method;

基于弯曲成形法抛物面高速研磨的研究

3.

Research on the Lapping Uniformity of Uncertain Eccentricity Plane Lapping;

不定偏心平面研磨均匀性的研究

5) polishing

研磨

1.

Polishing Robot System and the Control of Its Motion;

研磨机器人系统及其运动控制

2.

A new way of polishing is discussed, in which the ultrasonic energy is applied to the interface of mechanical polishing and correlative equipment and experimental equipment are designed.

为了提高光纤连接器端面的加工效率和加工质量,改善连接器光传输性能,探讨了在机械研磨的界面上引入超声能的复合研磨方式,设计了相应的超声机械研磨装置。

3.

To improve the material removal rate(MRR),this paper discussed a new ultrasonic polishing in which the ultrasonic energy was introduced to the interface of common polishing,and compared this new polishing process with the common polishing process in the MRR.

为了提高机械研磨的材料去除率,探讨了在机械研磨的界面上引入超声能的复合研磨方式,将机械研磨和引入超声的复合研磨两种方法的去除效率进行了实验对比;发现复合研磨后,去除效率有显著提高;得出超声/机械复合研磨的加工效率明显优于机械研磨。

6) grind

研磨

1.

Siemens S7-300 PIc In Paper making Grinding Production Line Application;

西门子S7-300 PLC在造纸研磨生产线中的应用

2.

The applications of the different grinding media in the grind of ink were summarized in this pa- per.

介绍不同的研磨介质在油墨中的应用,并讨论了研磨介质的种类,体积比及尺寸对基料细度的影响。

3.

The grind renovation processes of rough grind,fine grind and polishing are analyzed.

介绍拉丝模模坯、模套的加工及模芯装镶过程中应注意的要点 ;给出拉丝模修复常用研磨剂的特性和应用范围 ,比较了几种研磨剂研磨效率 ;分析粗磨、细磨和精磨、抛光的研磨修复工

7) rubbing

研磨

1.

Finishing treatment of plating deposit and conversion coating—drawing, rubbing and double-color treatment;

镀层及转化膜的精饰处理──拉丝、研磨及双色处理

2.

In order to improve machining precision and rubbing efficiency of HIPSN( Hot - Isostatic Pressed Silicon Nitride) ceramic ball and to reduce its rubbing cost, a new rubbing method of ceramic ball, called Taper Rubbing, was developed.

为了提高热等静压氮化硅(HIPSN)陶瓷球的研磨效率和精度,降低其研磨成本,本文设计和研制了一种新的陶瓷球研磨方法--锥形研磨法;探讨了该方法下陶瓷球表面研磨迹线的分布规律。

3.

This paper introduces the progress of MRF rubbing technology, its principle of application and key technique.

介绍了磁流变研磨技术的发展、应用原理及关键技术,讨论了磁流变抛光液的制备及其性能对磁流变研磨工艺的影响。

8) grind

(研)磨

9) grinding

(研)磨

10) milling

(研)磨

补充资料:研磨

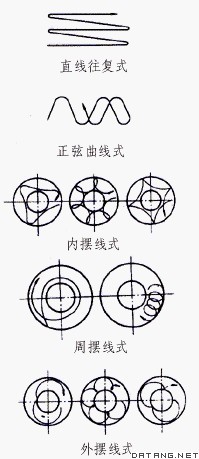

| 研磨 lapping 利用涂敷或压嵌在研具上的磨料颗粒(研磨剂),通过研具与工件在一定压力下的相对运动对加工表面进行的精整加工。工件在研磨前要经过精磨等预加工,所留研磨余量一般为0.005~0.03毫米 。研磨后加工精度可达IT5~01,表面粗糙度可达0.63~0.01微米 。研磨可用于加工金属和非金属材料的多种表面,如平面、圆柱面、圆锥面、螺纹、齿面、球面等。单件小批量生产时用手工研磨,批量较大时用机械研磨。研具的硬度应比工件低一些,耐磨性要好,常用材料有灰铸铁、软钢、黄铜、紫铜等。研磨剂为磨料和油脂等调和而成的混合物,有液态、膏状和固态3种。为了减少切削热,研磨一般在低压、低速条件下进行。粗研时压力小于0.3兆帕 ,速度为20~120米/分;精研时压力为0.03~0.05兆帕,速度为10~30米/分。两个相配的工件,可以配研,两者互为研具,如阀座与阀芯,柱塞与柱塞套等。配研后可以达到很好的气、液密封配合。配研偶件只能成对使用,不具互换性。

|

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条