1) cracks in the eccentric position of welded joint

焊缝偏心裂纹

2) cracks in the center of welded joint

焊缝中心裂纹

3) Welding crack

焊缝裂纹

1.

By means of the analyzing for the reason resulting in the welding crack in a strengthening tendon-plate of a pressure vessel,the article puts forward the method that has resolved the problem having common phenomenon in pressure vessel operation and has been proved to be effective through practical application in years.

本文通过压力容器接管加强筋板焊缝裂纹产生原因的分析,提出了解决这一带有普遍现象问题的方法,并经实际运行证实了该方法的可行性。

2.

By analyzing the effect of the material welding capability, welding structure, warm-up, heat treatment after welding and crafts parameter on welding crack in shore crane, the paper put forward the improving measure and acquires favorable result.

从材料的焊接性能、焊接结构、焊条、预热与焊后热处理、焊接工艺参数等角度对岸吊胎架焊缝裂纹进行了分析,提出了改进措施,取得了良好的效果。

4) weld crack

焊缝裂纹

1.

Through analysis on inside weld forming and welding procedure of SSAW pipe,it pointed out weld crack is easy to appear in brittle temperature zone in welding pool.

通过对螺旋埋弧焊管内焊缝成型和焊接过程的分析,指出焊缝裂纹易产生在焊接熔池脆性温度区。

2.

The hydrogenation pipe would weld crack after running for some time as high temperature and high pressure, and the phenomenon was rare.

高温高压临氢管道运行一段时间发现多道焊缝裂纹,较为罕见。

5) crack

[英][kræk] [美][kræk]

焊缝裂纹

1.

By application of CO_2 arc welding on assembly and process of blast furnace stack casing,it prevent from welding distortion and crack efficiently,also it points out that enhancing welding quality needs observation and thinking over initially,and extending the application of CO_2 arc welding from cost,welding quality and training.

通过对CO_2气体保护焊在高炉炉壳组装与焊接工艺的使用,有效地控制了焊接变形及防止焊缝裂纹,阐明提高焊接质量要从多元角度出发,有机整体地考虑问题,在结论中进一步从成本、焊接质量及培训等方面分析证明推广CO_2气体保护焊的必要性犤1,2犦。

补充资料:在AutoCAD中偏心圆锥与偏心圆台实体的画法

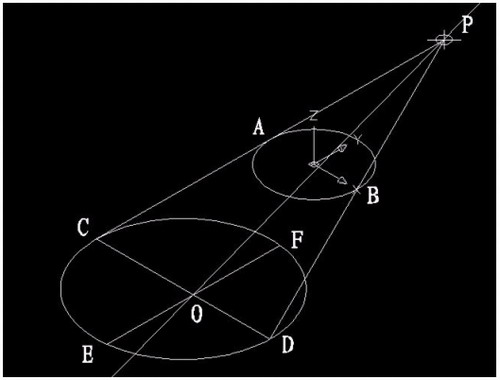

现在要画一个偏心圆锥,底面在WCS的XY平面上,圆心(0,0,0),半径100,顶点(300,0,400)在ZX平面上.

1)连接PA,PB. A(-100,0,0) B(100,0,0)

图1

在当前坐标下:

2)延长PA到C,使PA=CA;延长PB到D,使PB=DB;

3)连接CD;

4)以CD为直径画圆;

5)用XLINE命令中的二等分选项作角CPD的角平分线PO,交CD于O;

6)过O作CD的垂线,交圆于E,F;

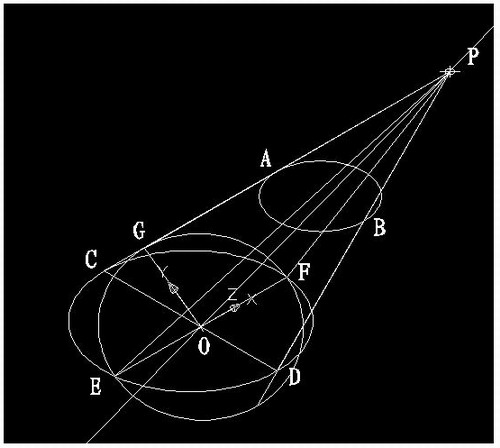

图2

7)用三点UCS命令,取三点为:O,P,C;

8)过点O作PO的垂线GO,交PC于G;

图3

9)再次用三点UCS命令,取三点为O,F,G;

10)现在就可以画椭圆锥了!

cone-e-c-捕捉O点-捕捉F点-捕捉G点-a-捕捉P点;

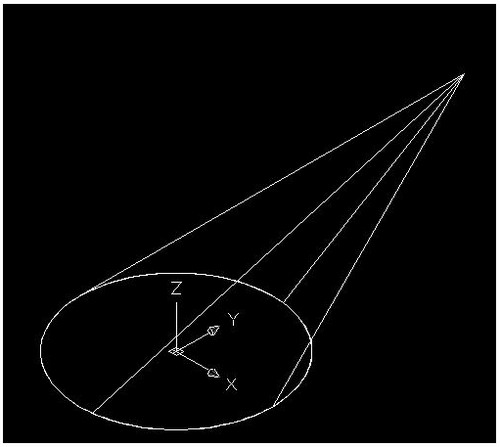

图4

11)回到WCS,剖切椭圆锥

SL-选择椭圆锥-回车-XY-回车-捕捉P点.

12)删除辅助线条.

图5

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条