1) welding influence

焊接影响

2) weld heat-affected zone

焊接热影响区

1.

The fatigue crack growth (FCG) behavior of the weld heat-affected zone of 14MnNbq bridge steel was systematically investigated in this paper.

该文系统地研究了14MnNbq桥梁钢焊接热影响区的疲劳裂纹扩展行为。

3) heat affected zone(HAZ)

焊接热影响区

1.

The simulated heat affected zone(HAZ)continuous cooling transforming curve of X70 pipeline steel was measured by thermal simulated test,microstructural and hardness analysis,and the microstructure of simulated HAZ was investigated.

利用热模拟技术并结合组织分析和硬度测试,测定出X70管线钢焊接热影响区连续冷却转变曲线并研究其组织转变规律。

2.

The coarse grained structure of heat affected zone(HAZ) was gained through the thermal simulating method.

通过热模拟方法使试样获得焊接热影响区的粗晶组织 ,然后将模拟试样加工成标准夏氏冲击试样 ,经 5 0 0、5 2 0、5 5 0、5 80、6 0 0、6 2 0、6 5 0℃等 7个不同温度进行去应力退火。

3.

The effects of welding thermal cycle on impact toughness of coarse grain heat affected zone(HAZ)of two kinds X80 pipeline steels,namely Mn-Mo-Nb steel and high-Nb HTP pipeline steels,were investigated by means of welding thermal simulation on Gleeble-3500 simulator.

采用Gleeble-3500型热模拟试验机,研究了焊接热循环对Mn-Mo-Nb和高铌HTPX80管线钢焊接热影响区(HAZ)冲击韧性的影响。

4) HAZ

焊接热影响区

1.

Comparison of Crystalline Ggrain Size of Ultra Fine Grain Steel and Mild Steel in HAZ;

超级钢与低碳钢焊接热影响区晶粒尺寸对比

2.

SCC at HAZ of Vapor Pipes Fabricated by SUS304L Stainless Steel;

不锈钢气相管焊接热影响区应力腐蚀开裂研究

3.

Prediction of grain size in the HAZ of the ultrafine grain steel joint;

400MPa级超级钢焊接热影响区晶粒尺寸的预测

5) heat affected zone

焊接热影响区

1.

Microstructure simulation of grain growth in heat affected zone;

焊接热影响区晶粒长大过程的微观组织模拟

2.

In order to study the welding technique of HNS, the microstructure and hardness of heat affected zone (HAZ) of HNS were investigated by simulation on a Gleeble-1500 thermal simulator.

作者对高氮钢焊接热影响区(HAZ)的组织和硬度进行了研究。

3.

In this paper,the brittle fracture probability of weldments and the fracture toughness of heat affected zone (HAZ) were investigated according to the principle of the weakest link theory.

从最弱链模型的物理本质出发,探讨了影响焊接热影响区脆性断裂的主要因素。

6) Welding heat affected zone

焊接热影响区

1.

The effect of helium on the irradiaion damage characteristics and radiation induced segregation at grain boundaries in the welding heat affected zone(HAZ) of Fe-Cr-Mn(W,V) alloy for fusion-fission mixed reactor was investigated by super-high voltage electron microscopy connected with a high energy ion accelerator.

采用高能离子加速器和超高压电镜连接装置 ,研究注入He后电子辐照和同时辐照 (He+ e-)低活性Fe Cr Mn(W ,V)合金焊接热影响区 (HAZ)损伤组织特点 ,测定He对损伤组织内晶界附近合金元素浓度变化的影响。

2.

In frequent bending stress condition,fatigue cracking occurred due to the cracking source had been initiated in welding heat affected zone.

在承受频繁的弯曲应力作用后,在其焊接热影响区萌生了裂纹源进而发生疲劳开裂。

3.

A method of Monte Carlo combined with welding experiments was adopted to study the grain size and microstructure in welding heat affected zone of the ferrite stainless steel.

本文采用蒙特卡罗方法,结合焊接工艺实验,研究了铁素体不锈钢焊接热影响区(HAZ)的晶粒度和微观组织。

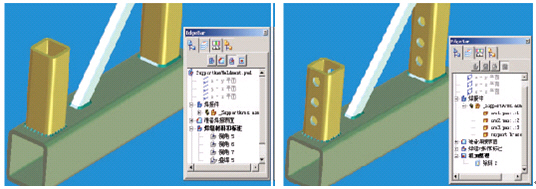

补充资料:Solid Edge焊接设计

Solid Edge在装配环境中还提供一套专用命令用于焊接件的设计。焊接是在装配环境中在指定焊接件上设计焊缝、表面处理、焊接标注和焊后加工处理等。Solid Edge的制图模块可产生焊前和焊后视图,从而完整表达焊接工序。

专业焊接设计工具

装配环境中的装配特征功能,能提供各种的材料处理的能力,如:材料去除、倒角、旋转拉伸、放样拉伸、打孔等,满足焊前表面预处理、添加焊料到焊后机加工等。用户可以采用和零件设计中一样的设计方法,去完成各种各样的操作,而无需学习新的操作命令。与加工过程一致的控制界面既便于学习,又提高了设计效率。

焊前预处理

使用装配特征提供的诸如倒角、开孔、除料等命令对施行焊接的构件表面进行材料去除的操作,该类操作行业上称之为焊前处理,如采用各种手段打坡口等。

添加焊筋

在焊接处可以添加焊料以反映焊接后机件的真实状况。也可以对焊缝进行标注,以便在生成工程图时直接引用。Solid Edge可以提供自动角焊、坡口焊、跳焊等方法,同时也可以利用Solis Edge提供的多种材料添加功能,用手工的方法定义各种类型的特殊形状的焊筋。

焊后机加工

焊接件完成以后,可以对焊接件进行开孔等机加工。此时添加的特征不会对原来的零件产生影响。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条