1) hydrodynamic forces of water-exit

出水水动力

1.

Parameter identification of hydrodynamic forces of water-exit body based on TSK fuzzy system;

基于TSK智能技术的物体垂直出水水动力参数辨识研究*

2) water-exit dynamics

出水动力学

3) artesian aquifer power

承压出水动力

4) hydraulic extrusion

水力挤出

1.

Research and application of coal and gas outburst control measure based on hydraulic extrusion in roadway;

煤巷水力挤出防突措施的研究与应用

2.

Protection against outburst mechanism of hydraulic extrusion measure in the front of coal road heading face;

煤巷掘进工作面水力挤出措施防突机理

3.

Aim at the problems of coal and gas outburst,slowness of advancing,malajustment of exploitation and grubbing and strain of production in grubbing work-face,hydraulic extrusion has been applied in Dazhong mine of Anyang.

针对安阳大众煤矿煤巷掘进工作面具有严重突出危险、推进速度缓慢等问题,在掘进工作面试验了水力挤出消突措施。

5) hydraulic screen

水力挤出

1.

The depth of sealing hole is a very important factor in hydraulic screen;according to the condition of Sang Shu-ping coal mine,base the theoretically analyse and though the checkout,make sure the logical depth of sealing hole of hydraulic screen in Sang shu-ping coal mine,good effect was obtained,and carrying out rapid excavation.

水力挤出的封孔深度是影响消突效果的重要因素之一,以理论分析为基础,结合韩城桑树坪煤矿的实际情况,经过实践考察分析,确定了桑树坪煤矿水力挤出的合理封孔深度,取得了明显的效果,实现了安全快速掘进。

6) hydraulic pressing

水力挤出

1.

In order to removing tunneling working surface outburst quickly and effectively,combine the Six Mineral coal beds characteristics,hydraulic pressing are taken to remove outburst measure.

为了快速、有效地消除煤巷掘进工作面的突出危险性,结合六矿煤层赋存特点,采取水力挤出消突措施。

2.

Based on data gained from in - site , ANSYS finite element analysis software is used , numerical value simulation was carried out in stress distribution、mechanics property、 methane removal of coal body which is located in front of drivage face before and after taking hydraulic pressing measures.

以现场实测数据为基础,利用ANSYS有限元分析软件,对水力挤出措施实施前后的掘进工作面前方煤体应力分布、力学性质、瓦斯运移进行数值模拟,研究了水力挤出措施的消突机理。

补充资料:动力机械:内燃机动力学

研究内燃机运转中的力学现象的科学。其主要任务是研究分析内燃机运转时各主要零件的运动规律及其受力情况﹐用以作为内燃机零件设计﹑计算的依据。它还研究这些力对内燃机动力装置的影响及其消减方法。内燃机动力学的主要内容为曲柄连杆机构运动学﹑曲柄连杆机构动力学和内燃机平衡分析等。

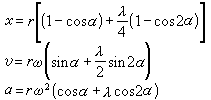

曲柄连杆机构运动学 研究曲柄﹑连杆﹐尤其是活塞的运动规律。活塞作周期性往复运动时的位移 、速度

、速度 和加速度

和加速度 可用下述各式近似求算

可用下述各式近似求算

式中 为曲轴转角﹔

为曲轴转角﹔  为曲轴旋转角速度﹔

为曲轴旋转角速度﹔ 为曲柄半径﹔

为曲柄半径﹔ 为曲柄半径

为曲柄半径 与连杆长度

与连杆长度 之比﹐即

之比﹐即  =

=  /

/

曲柄作回转运动﹐连杆作复杂的平面运动。连杆的运动往往被简化分解为随活塞组的往复运动和随同曲柄的旋转运动。

曲柄连杆机构动力学 研究分析曲柄连杆机构(见曲柄滑块机构)在运动中力的生成﹑传递和输出。作用在曲柄连杆机构上的力有曲柄连杆机构运动时产生的往复惯性力和离心惯性力﹐以及内燃机气缸内的气体压力。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条