1) creep life model

蠕变持久寿命模型

1.

The double shear creep specimens have been applied to validate the raftin g prediction criterion and creep life models.

利用双剪切蠕变试样在受剪切区的筏化试验结果和不同晶体取向试样的蠕变持久寿命试验结果,对镍基单晶合金的蠕变筏化预测模型和蠕变持久寿命模型进行考核,证实此2个模型的合理性。

2) stress rupture life

持久寿命

1.

The influence of rare earth cerium atom on the amount,morphology and distribution of the grain boundary phase of Fe-Cr-Ni-Nb-Ti-Al-W alloy was investigated,and the relationship between the above characteristics and the stress rupture lifes of the test alloys was discussed.

研究了稀土元素铈对铁基合金Fe-Cr-Ni-Nb-Ti-Al-W晶界析出相的数量、形貌、分布的影响及其与持久寿命的关系。

2.

365, the high temperature ductility and stress rupture life were reduced because large MC films, dendritic flake M6C and fine M23C6 films precipitated at grain boundaries.

008%时,因固溶B/C(原子比)很低,晶界析出大尺寸MC薄膜和M6C枝晶片以及薄膜状M23C6,不利于高温塑性和持久寿命。

3.

The stress rupture life is found to be remarkably improved with Re addition but the strengthening effect .

结果表明:在高温高应力条件下,随合金中Re含量的单独增加,合金高温高应力持久寿命提高,而单位质量Re元素的强化作用减弱;合金Cr含量对合金高温高应力持久寿命有显著影响,Re含量增加的同时适当降低合金Cr含量,可使合金获得较高的持久寿命。

3) endurance life

持久寿命

1.

The endurance life and fracture behaviors of directionally solidified superalloy DZ4 after pre-deformation and heat treatment were tested and analyzed.

对定向凝固DZ4合金机械预变形和热处理后的持久寿命与断裂行为进行了测试与分析,研究了再结晶对定向凝固DZ4合金持久行为的影响机制。

2.

We select material from representational part of turbine blade in order to increase the reliability of design parameters and design method for endurance life of turbine blade,.

某定向结晶镍基高温合金用于制造我国目前最先进的某在研型号发动机的高压涡轮叶片,为了提高该涡轮叶片持久寿命设计参数选取和设计方法的可靠性,从涡轮叶片代表性部位取材并设计、加工试验试件。

4) creep life

蠕变寿命

1.

Creep tests of P91 base material and its welds have been carried out,the creep behavior of P91 studied and creep rupture strength extrapolated by the Isothermal and the L-M parameter methods,followed by creep life estimations of P91 fresh steam pipes.

对P91钢母材和焊接接头进行持久试验,研究P91钢的蠕变特性,采用等温线法和L-M参数法对持久强度进行外推,进而对P91钢制主蒸汽管道的蠕变寿命进行估算。

2.

The causes of rigidity change are concluded,and T92 steel s approximate creep life is extrapolated based on rigidity method.

针对T92铁素体钢高温时效后的硬度变化进行了详细的实验分析研究,归纳了硬度变化的原因,并结合实验数据,根据硬度法外推出T92钢的大致蠕变寿命,认为T92钢能够满足超超临界机组600~650℃温度环境下的使用要求。

3.

Multi-axial creep testing methods are generalized,and then the method of how to evaluate the creep life of high temperature components based on creep testing data is presented.

综述了多轴蠕变的试验方法,并推荐了基于试验数据评价工程结构蠕变寿命的参考应力法。

5) creep rupture life

蠕变寿命

1.

Results indicate that the spreading area of the composite solder with 5% Ag particles is largest,the wetting angle smallest,and its creep rupture life longest,which is 23 times more than one of the matrix solder at the same experimental condition.

结果表明:当Ag含量(体积分数)为5%时,复合钎料铺展面积最大,润湿角最小,钎焊接头蠕变寿命最长,比基体钎料提高23倍。

2.

Creep rupture lifetimes of Cu particle enhancement SnPb based composite solder joints and the matrix solder joints are tested under different temperatures and stresses and the creep rupture mechanism is analyzed.

测定不同应力和温度下Cu颗粒增强复合钎料及基体钎料钎焊接头蠕变寿命,分析Cu颗粒增强复合钎料及其基体钎料63Sn37Pb钎焊接头蠕变断裂机理。

3.

The creep rupture lifetimes of Ag particle enhancement SnPb based composite solder joints and matrix solder joints were respectively tested under different temperatures and stresses,and the creep rupture mechanism was analyzed.

测定了不同应力和温度下Ag颗粒增强复合钎料及基体钎料63Sn37Pb钎焊接头蠕变寿命,分析了Ag颗粒增强复合钎料及基体钎料钎焊接头蠕变断裂机理。

6) short-term creep rupture life

短时持久寿命

1.

The relationship between high-temperature short-term creep rupture life and microstructures of GH586 alloy has been investigated by heat treatment.

通过改变热处理制度使合金获得不同的显微组织 ,研究了GH5 86合金高温短时持久寿命与显微组织的关系。

补充资料:AutoCad 教你绘制三爪卡盘模型,借用四视图来建模型

小弟写教程纯粹表达的是建模思路,供初学者参考.任何物体的建摸都需要思路,只有思路多,模型也就水到渠成.ok废话就不说了.建议使用1024X768分辨率

开始

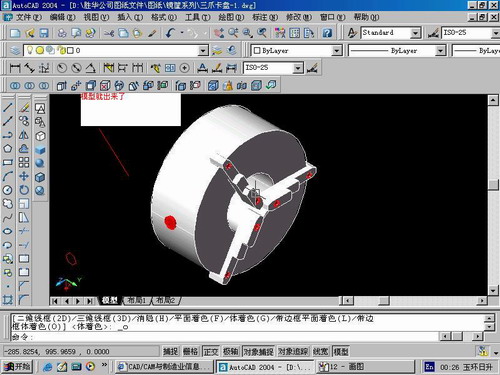

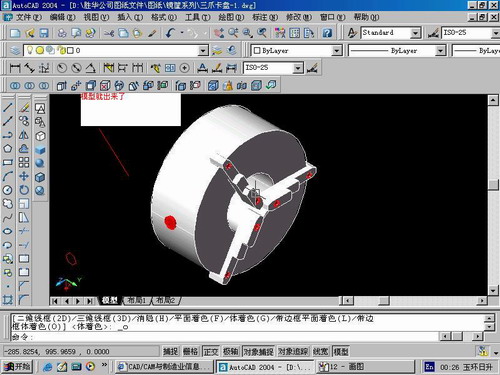

先看下最终效果

第一步,如图所示将窗口分为四个视图

第二步,依次选择每个窗口,在分别输入各自己的视图

第三步,建立ucs重新建立世界坐标体系,捕捉三点来确定各自的ucs如图

第四步,初步大致建立基本模型.可以在主视图建立两个不同的圆,在用ext拉升,在用差集运算.如图:

第五步:关键一步,在此的我思路是.先画出卡爪的基本投影,在把他进行面域,在进行拉升高度分别是10,20,30曾t形状.如图:

第六步:画出螺栓的初步形状.如图

第七步:利用ext拉升圆,在拉升内六边形.注意拉升六边行时方向与拉升圆的方向是相反的.

之后在利用差集运算

第八步:将所得内螺栓模型分别复制到卡爪上,在利用三个视图调到与卡爪的中心对称.效果如图红色的是螺栓,最后是差集

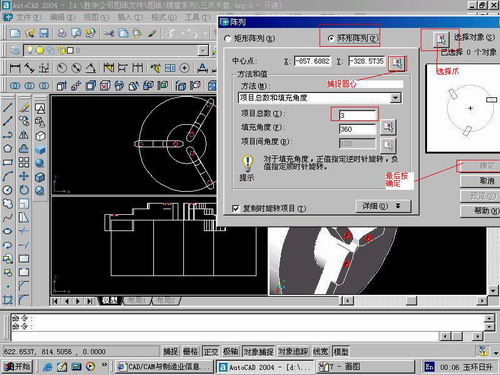

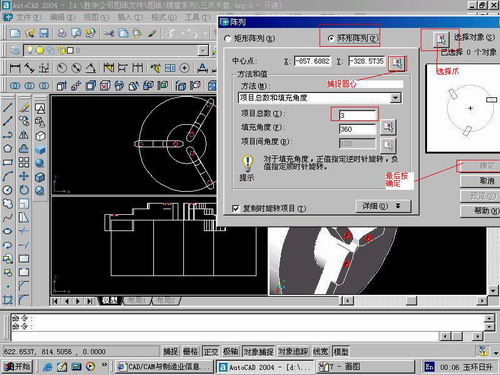

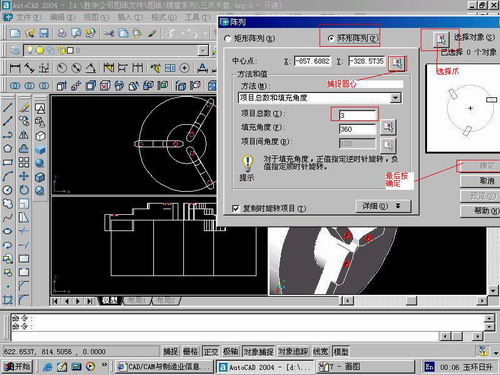

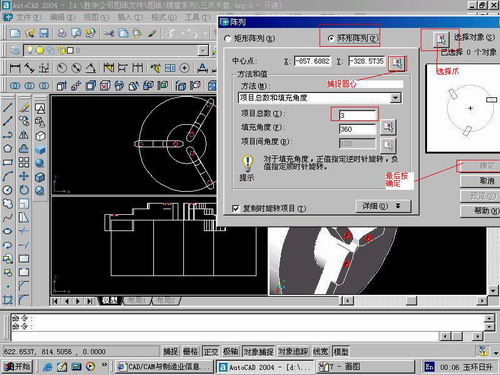

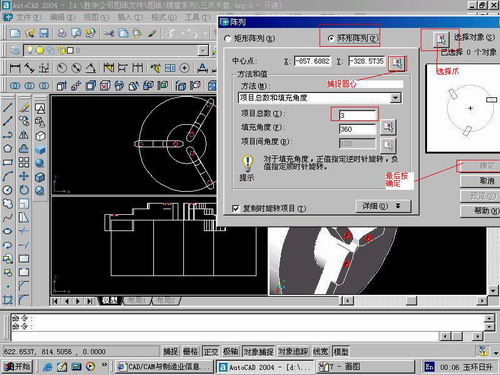

第九步:阵列

第10步.模型就完成了

来一张利用矢量处理的图片

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条