2) size of crystal

晶体尺寸

1.

So the size of crystals is very important to the energy resolution.

因此对晶体的尺寸提出了较高的要求,要求晶体尺寸长度误差(-1~+1)mm,宽度误差为(0~-200)μm。

3) austenite grain size

奥氏体晶粒尺寸

1.

?The dynamic recrystallization and austenite grain size after recrystallization in a new MnCr gear steel were studied at a strain up to 07, at a range of temperature from 850 to 1?150?℃, at strain rate from 01 to 1 s-1 and at initial austenite grain size from 70 to 150?μm using a Gleeble 1500 thermomechanical test system.

1~1s-1,变形温度为850~1150℃,原始奥氏体晶粒尺寸为70~150μm条件下的动态再结晶行为及再结晶后奥氏体晶粒尺寸的变化规律·研究结果表明:在一定的变形量下,变形速率、变形温度、奥氏体晶粒尺寸是影响再结晶的3个因素,只有变形条件Z小于上临界值Zc时才会发生动态再结晶·再结晶后奥氏体晶粒尺寸 D是由变形条件Z惟一地决定而与原始奥氏体晶粒大小无关,Z增加, D减小,二者符合关系式Z=A D-3。

2.

At the same time, effects of rolling temperature and deformed amount on austenite grain size in AH36 steel were also studied with duo mill.

在轧制温度一定时 ,变形量和钛含量增加 ,奥氏体晶粒尺寸减小。

4) ferrite grain size

铁素体晶粒尺寸

1.

Double experiments of controlled rolling/cooling process were carried out on a lab mill and the results showed that the effect of ferrite grain size on the mechanical properties is greater than that of pearlite morphology for the low-carbon cold heading steel.

对低碳铆螺钢采用两次控轧控冷试验,结果表明,铁素体晶粒尺寸比珠光体形态对低碳铆螺钢力学性能的影响要大。

2.

A study on effect of reversing cold rolling on texture and ferrite grain size of DX51D(LCAK steel) and DX54D(IF steel) has been done by simulating experiment of reversing and continuous cold rolling and annealing in the laboratory.

在实验室通过可逆式和连续式冷轧及退火模拟试验,研究了可逆式冷轧对DX51D(低碳铝镇静钢)和DX54D(无间隙原子钢)钢板织构及铁素体晶粒尺寸的影响。

5) grain size

晶粒尺寸

1.

Influence of wire rolling process parameters on austenite grain size of high carbon steel;

高碳钢线材轧制工艺参数对晶粒尺寸的影响

2.

Prediction of the flow behavior and grain size during forming for nickel alloy heavy forging;

镍基合金大锻件成形过程流变行为与晶粒尺寸预测

3.

Modelling for grain size and flow stress of magnesium alloy based on BP neural network;

基于BP神经网络的镁合金晶粒尺寸及流变应力模型

6) crystallite size

微晶尺寸

1.

The increase of crystallite size and notable changes of orientation factor for crystal planes during blow molding process reveale.

结果表明经过吹塑成型过程后,TPCC的熔融温度、结晶度均较TPC有所提高,DSC熔融半峰宽明显下降,微晶尺寸明显增大,同时晶面取向因子发生显著变化,表明成型过程中晶区尺寸增大,且晶体结构更均匀规整,赋予了输液瓶良好的性能。

2.

The crystallite size, degree of crystallinity( X c) and thermal properties of the [poly(cyanoarylether PCE)] at various temperatures have been studied by using WAXD and DSC.

利用广角 X射线衍射 (WAXD)方法和示差扫描量热法 (DSC)研究了不同热处理温度时聚芳醚腈 (PCE)的微晶尺寸、结晶度及热性能的变化。

3.

The resultsshowed that after the treatment of cellulose with L-NH3, the lateral order distribution,crystallinity, crystallite size and lattice form of cellulose were dramatically changed.

结果表明,液氮处理后纤维素的侧序分布、结晶度、微晶尺寸、晶格形态都发生深刻的变化。

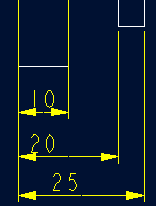

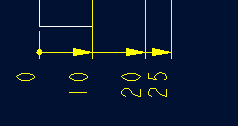

补充资料:工程图标准尺寸及坐标尺寸

标准标注类型,是我们常用的标注类型。而坐标标注是便于数控加工采用的另一中标注形式。PRO/E可以将两种标注方式进行转换。

· 3.2 标准标注到坐标标注的转换

注意: 转化为坐标标注的尺寸必须是线性标注的,下列尺寸不能转化为坐标标注:

- 被显示成线性尺寸的直径

- 中心线尺寸

- 选择MODIFY DRAW > Dim Params > Dim Type > Ordinate Dim > Create Base.

- 选择作为参考基准线的尺寸

- 选择基准的引出线,该点为0点

- 选择 MOD DIM TYPE > Lin to Ord .

- 选择线性尺寸:注意:必须选择具有相同基准的尺寸

========>>>>

========>>>>

1. 选择 DIM PARAMS > Diam Dim Type .

2.点击Ord to Lin

3.选择尺寸即可

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条