1) spherulite size

球晶尺寸

1.

The mechanical properties,spherulite size,melting point and crystallinity of the anhydrite/PP composites and the anhydrite modified by modifer/PP composites were studied.

研究了硬石膏及其表面改性对聚丙烯(PP)复合材料的力学性能、球晶尺寸、熔点和结晶度的影响。

2.

At the same time,MB could decrease the spherulite size and the crystallization degree of polypropylene.

结果表明,成核剂MB较好地改善了聚丙烯的力学性能以及熔体流动性能,降低了聚丙烯球晶尺寸。

3.

The morphologies of nonisothermal crystallized isotactic polypropylene (IPP)and added 25 nucleating agents samples have been studied by PLM and SEM The effect of nucleating agents and cooling rates (A) on spherulite size (d) has been researched.

研究了IPP及其加25种成核剂时的非等温结晶形态,考查了成核剂和线性降温速率α对球晶尺寸d的影响。

2) grain size

晶粒尺寸

1.

Influence of wire rolling process parameters on austenite grain size of high carbon steel;

高碳钢线材轧制工艺参数对晶粒尺寸的影响

2.

Prediction of the flow behavior and grain size during forming for nickel alloy heavy forging;

镍基合金大锻件成形过程流变行为与晶粒尺寸预测

3.

Modelling for grain size and flow stress of magnesium alloy based on BP neural network;

基于BP神经网络的镁合金晶粒尺寸及流变应力模型

3) crystallite size

微晶尺寸

1.

The increase of crystallite size and notable changes of orientation factor for crystal planes during blow molding process reveale.

结果表明经过吹塑成型过程后,TPCC的熔融温度、结晶度均较TPC有所提高,DSC熔融半峰宽明显下降,微晶尺寸明显增大,同时晶面取向因子发生显著变化,表明成型过程中晶区尺寸增大,且晶体结构更均匀规整,赋予了输液瓶良好的性能。

2.

The crystallite size, degree of crystallinity( X c) and thermal properties of the [poly(cyanoarylether PCE)] at various temperatures have been studied by using WAXD and DSC.

利用广角 X射线衍射 (WAXD)方法和示差扫描量热法 (DSC)研究了不同热处理温度时聚芳醚腈 (PCE)的微晶尺寸、结晶度及热性能的变化。

3.

The resultsshowed that after the treatment of cellulose with L-NH3, the lateral order distribution,crystallinity, crystallite size and lattice form of cellulose were dramatically changed.

结果表明,液氮处理后纤维素的侧序分布、结晶度、微晶尺寸、晶格形态都发生深刻的变化。

4) crystallite size

晶粒尺寸

1.

Determination of crystallite size and strain by X-ray powder

晶粒尺寸和应变的X射线粉末衍射法测定

2.

The effects of the amount of Gd~ 3+ -doping and calcination temperature on the photocatalytic activity for photocatalytic degradation of methylene blue (MB) in aqueous solution, phase structure, crystallite size, surface texture properties of the nanopowders were investigated,and t.

研究了Gd3+掺杂量和焙烧温度对样品光催化降解亚甲基蓝的活性、相结构、晶粒尺寸和表面织构特性的影响,并结合表面光电特性和表面组成等探讨了Gd3+掺杂对纳米TiO2的光催化活性的影响机制。

3.

The effects of pHinitial value, hydrothermal temperature and hydrothermal time on the morphology, crystal phase and crystallite size of TiO2 powder were investigated.

研究了反应初始pH值、水热反应温度和水热反应时间对TiO2形貌、物相和晶粒尺寸的影响。

5) crystalline size

晶粒尺寸

1.

When Si and C contents were higher, Ti (C, N) changed to TiC and the crystalline size decreased to 2—4nm.

用脉冲直流等离子体辅助化学气相沉积(PCVD)方法在高速钢基体上沉积出新型Ti-Si-C-N超硬薄膜,Ti-Si-C-N薄膜为纳米晶/非晶复合结构(nc-Ti(C,N)/a-Si_3N_4/a-C—C),当薄膜中Si和C含量较高时,Ti(C,N)转变为TiC,晶粒尺寸减小到2—4 nm,薄膜晶粒尺寸和硬度的高温热稳定性均随沉积态薄膜中的原始晶粒尺寸减小而提高,当原始晶粒尺寸在8—10 nm之间时,晶粒尺寸和硬度热稳定性可达900℃;当原始晶粒尺寸在2—4 nm之间时,晶粒尺寸和硬度热稳定性可达1000℃,薄膜硬度和晶粒尺寸表现出同步的高温热稳定性,分析认为由调幅分解形成的纳米复合结构中的非晶相强烈地抑制晶界滑移与晶粒长大,从而使Ti-Si-C-N薄膜的热稳定性显著提高。

2.

The effects of pH value,hydrothermal temperature and time on the morphology and crystalline size of nanoscale rutile TiO_2 were discussed.

研究了pH值、水热反应温度和水热反应时间对金红石型纳米二氧化钛形貌和晶粒尺寸的影响。

3.

Influence of chromium additions on the crystalline size and magnetic properties of nanocom-posite Nd2Fe14B/.

5,1,2)的纳米晶复合永磁合金,研究了Cr的添加对合金晶粒尺寸及磁性能的影响,结果表明适量Cr的添加能有效抑制磁性相晶粒长大,提高了合金的矫顽力。

6) crystal size

晶粒尺寸

1.

The crystal size of α-Fe is calculated from XRD pattern using Scherrer formula.

铁基非晶材料通过热处理发生了纳米晶化过程,用X射线衍射仪和透视电镜检测了该过程材料的结构和组织,特别是晶粒尺寸的变化,利用Scherrer公式计算了晶化过程中产生的α-Fe颗粒的尺寸大小。

2.

XRD results indicate that the NiO nanowire has a face-cubic structure and its average crystal size i.

测试结果表明:NiO纳米线为面心立方结构,平均晶粒尺寸为50nm,纳米线直径约90nm,与模板孔径相当;长度约为25μm,并受镍纳米线沉积时间的影响;在紫外灯(365nm)照射下,40V比60VNiO/AAO阵列体系的光电压大。

3.

0Pa,catalysis electrode films of NiFe,CoMo of HER prepared at different sputtering pressure,their crystal size and HER overpotential decreased with increasing of chamber pressure,and their overpotential and Tafel slope were changed sharply at 2.

0Pa的范围内,不同溅射腔气压条件下制备的电极材料的晶粒尺寸、析氢反应的过电位与气压的关系,结果显示过电位随气压升高而降低,而且在2。

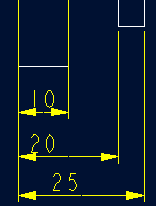

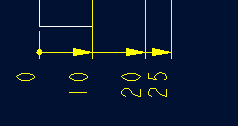

补充资料:工程图标准尺寸及坐标尺寸

标准标注类型,是我们常用的标注类型。而坐标标注是便于数控加工采用的另一中标注形式。PRO/E可以将两种标注方式进行转换。

· 3.2 标准标注到坐标标注的转换

注意: 转化为坐标标注的尺寸必须是线性标注的,下列尺寸不能转化为坐标标注:

- 被显示成线性尺寸的直径

- 中心线尺寸

- 选择MODIFY DRAW > Dim Params > Dim Type > Ordinate Dim > Create Base.

- 选择作为参考基准线的尺寸

- 选择基准的引出线,该点为0点

- 选择 MOD DIM TYPE > Lin to Ord .

- 选择线性尺寸:注意:必须选择具有相同基准的尺寸

========>>>>

========>>>>

1. 选择 DIM PARAMS > Diam Dim Type .

2.点击Ord to Lin

3.选择尺寸即可

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条