1) magnetic belt type conveyer

磁性带式输送机

2) magnetism-cushioned belt conveyor

磁垫式带式输送机

1.

This paper analyzes the structure, working priciple and main parameters of the external magnetism-cushioned belt conveyor, and pointes out that the product has developmental value.

分析了国外磁垫式带式输送机的结构、工作原理和主要技术指标,指出该产品在我国具有研究开发价值。

3) belt conveyor

带式输送机

1.

Discussion on balance issue of multi motor towing power for belt conveyor;

带式输送机多机拖动功率平衡问题的探讨

2.

Design of belt conveyor with horizontal bend;

平面转弯带式输送机的设计与实现

3.

The common fault analysis and settlements in belt conveyor system;

带式输送机常见故障分析和处理

4) belt conveyer

带式输送机

1.

The present and future development of belt conveyer;

带式输送机的现状与发展趋势

2.

Centralized monitoring and control system of underground belt conveyer;

井下带式输送机集中监视与控制系统

3.

Introduction of adjustable steering service of belt conveyer;

带式输送机可调转向装置简介

5) belt type conveyer

带式输送机

1.

The analysis introduced the belt type conveyer common breakdown andthe accident occurs the reason and the processing means,from thepractice angle scientifically proposed strengthens the equipment themaintenance and the maintenance,has the prevention accident theoccurrence,displays the equipment potency the maximization,thepromotion mine pit safety in production.

介绍了带式输送机常见的故障及事故发生的原因及处理的办法,从实践的角度科学地提出加强设备的维护及保养工作,有效预防事故的发生,发挥设备效能的最大化,促进矿井安全生产。

2.

And carried on the reason to the belt type conveyer common breakdownto analyze and to propose the elimination means.

并对带式输送机常见故障进行了原因分析,提出了消除办法。

6) belt conveyors

带式输送机

1.

A calculation method for two drums driven belt conveyors wder the slipless condition;

双滚筒分别驱动带式输送机不打滑条件的计算

2.

This paper briefly introduced the principle and the technical characteristics of some common soft start device and effects on belt conveyors.

简要介绍几种常用的软启动装置的工作原理、特性和在带式输送机上的使用效果。

3.

From the view point of value project,this paper analyses the economic significance of the application of belt conveyors' plane bended device in bended roadway.

从价值工程角度,分析了带式输送机平面弯曲装置在弯曲巷道中应用的经济意义。

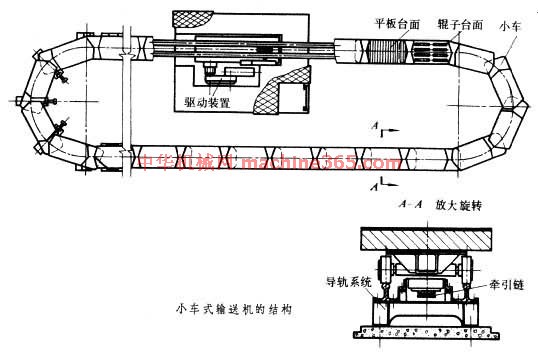

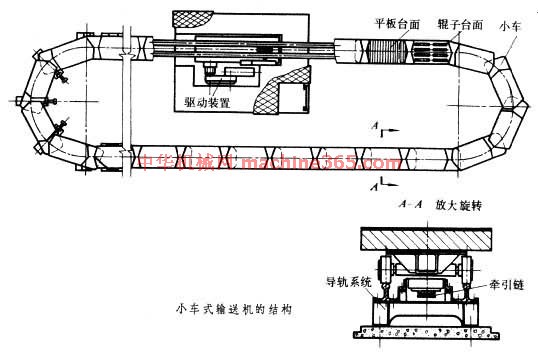

补充资料:物料搬运机械:小车式输送机

由链条牵引一系列小车在水平的环形闭合线路上低速运行以输送成件物品的输送机。在这种输送机上还可进行各种工艺操作。小车式输送机的各个分支都可作为工作分支﹐灵活地布置各项工艺操作。这种输送机尤其适宜于输送特殊形状或灼热对象﹐广泛用在机械﹑冶金等工业企业中﹐藉以组成机械化或自动化的流水生产线。例如﹐铸造过程中的造型﹑浇铸﹑冷却﹑落砂和砂箱运输等工序都可在同一台小车式输送机的不同区段上进行。小车式输送机一般由小车﹑牵引链﹑导轨系统﹑驱动装置和张紧装置组成(见图 小车式输送机的结构 )。不同结构的小车﹐适应不同的对象形状和各种工艺要求。小车式输送机的运行速度一般为3~6米/分﹐有的小车式输送机还可根据需要变速。

)。不同结构的小车﹐适应不同的对象形状和各种工艺要求。小车式输送机的运行速度一般为3~6米/分﹐有的小车式输送机还可根据需要变速。

)。不同结构的小车﹐适应不同的对象形状和各种工艺要求。小车式输送机的运行速度一般为3~6米/分﹐有的小车式输送机还可根据需要变速。

)。不同结构的小车﹐适应不同的对象形状和各种工艺要求。小车式输送机的运行速度一般为3~6米/分﹐有的小车式输送机还可根据需要变速。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条