1) Industrial fluidized bed boiler

工业沸腾炉

2) fluidized-bed furnace

沸腾炉

1.

Application of fluidized-bed furnace in 100 kt/a S-NPK fertilizer plant;

沸腾炉在100kt/a S-NPK复混肥生产中的应用

3) fluidized bed roaster

沸腾炉

1.

Process design of fluidized bed roaster in Jiangtong-Wengfu's 400 kt/a pyrite-based sulphuric acid plant;

江铜-瓮福400 kt/a硫铁矿制酸装置沸腾炉的工艺设计

2.

Revamping of slag tapping and transportation system for sulphuric acid fluidized bed roaster;

硫铁矿制酸沸腾炉排渣系统改造

3.

Design of fluidized bed roaster of a 100 kt/a sulphuric acid plant;

100kt/a硫酸装置沸腾炉的设计

4) fluidized bed furnace

沸腾炉

1.

Conceiving of Fluidized Bed Furnace Reformed from 35T Spreader-Stoker Boiler;

我公司35t抛煤机炉改造沸腾炉之设想

2.

The current drying modification is on coal instead of diesel oil for fluidized bed furnace with high efficiency and low dust (GXDF), which results in annual more than 20 million RMB Yuan from cost saving of drying DAP, as well as stable appearance, colour and high class DAP product.

采用低飞灰沸腾炉(GXDF),以烟煤为燃料进行技改,介绍其工艺流程、工艺参数及煤代油后所取得的效果:年节约烘干DAP燃料成本2000多万元,DAP外观颜色基本无变化,各项指标均达到优等品要求。

3.

It is the key of the automatic ore feed control system for fluidized bed furnace in ore based acid plant to maintain good control of the dynamic balance between the air (O 2) intake and ore (FeS 2) feed of the fluidized bed furnace, the air/ore ratio, and to maintain a weak oxidizing atmosphere in the furnace.

控制好沸腾炉进风量 (O2 )和进矿量 (FeS2 )之间的动态平衡关系———风矿比 ,维持沸腾炉内呈弱氧化气氛 ,是矿制酸装置的沸腾炉给矿自动控制系统的关键问题。

5) Fluid-bed furnace

沸腾炉

1.

In accordance with the problem of high sulfur content in dust produced by 30?m 2 fluid-bed furnace of 40 kt/a sulfuric acid system,suggustion of mixing high zinc slag into zinc concentrate was put forward to recovery high zinc slay,reduce impurity of roasted ore and improve benefit.

根据 40kt/a硫酸系列的 30m2 沸腾炉产出焙尘含硫高的问题 ,提出了在入炉锌精矿原料中配入高锌渣的生产方案 ,回收高锌渣和减少焙烧矿杂质含量创造的效

2.

Due to a few blast caps of 30m 2 fluid-bed furnace,resulting in low feed rate of concentrates and bad result of desulfur,after increasing numbers of bast caps,wind power was raised,output and quality of sinters were obviously improuved.

30m2 沸腾炉风帽数量少 ,致使精矿投料量低、脱硫效果差 ,增加风帽数量后 ,风量加大 ,焙烧矿产量及质量均有了明显的变

6) boiler slag

沸腾炉渣

1.

Extraction of aluminium and iron from boiler slag by sintering;

用烧结法从沸腾炉渣中提取铝和铁的研究

2.

Extraction of aluminium and iron content from boiler slag by sintering;

烧结法提取沸腾炉渣中的铝和铁

补充资料:工业炉:工业炉排烟系统

利用烟囱或机械装置将工业炉炉膛内的烟气排出炉外的系统。保证排烟通畅是工业炉正常使用的重要条件﹐排烟不通畅时﹐炉膛压力昇高﹐从炉膛四周的缝隙会逸出大量烟气而增加炉子的热损失﹐影响炉内气流的均匀分布﹐降低炉温均匀性﹐恶化操作环境。

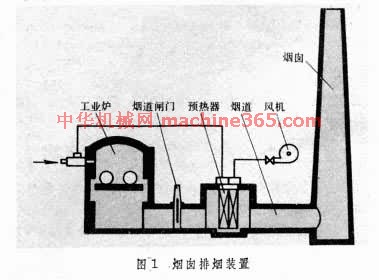

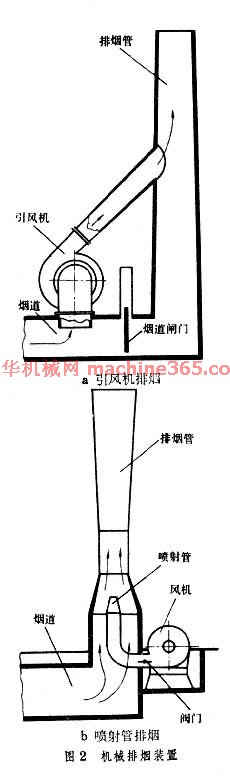

排烟系统是由產生抽力的排烟装置和排送烟气的烟道所组成。常用的排烟装置有烟囱(图1 烟囱排烟装置  )﹑引风机或喷射管(图2 机械排烟装置

)﹑引风机或喷射管(图2 机械排烟装置  )等。

)等。

烟囱排烟是靠流入烟囱内热烟气密度小於烟囱外空气密度所產生的浮力﹐以克服烟道的阻力。利用引风机也可将烟气排出﹐或在排烟系统中某一部位装设一个喷射管﹐用高速喷射气体所產生的负压排出烟气。烟囱排烟不消耗动力﹐排烟温度不受限制。当排烟阻力很大而工业炉又间断运行时﹐可用引风机或喷射管排烟。喷射管适用於排除高温烟气﹔引风机适用於排除低温烟气。

烟囱分为砖砌烟囱﹑混凝土烟囱和钢板烟囱。烟道有地下烟道和架空烟道两种。地下烟道多用砖砌﹐架空烟道宜採用衬有耐火材料的钢板製成。

为了减少烟气对环境的污染﹐或因节能需要而在烟道内设置预热器时﹐都需要儘量提高烟囱高度并增加烟囱出口处的烟气流速﹐使之大於当地最大风速或至少不低於3米/秒﹐以避免烟气中的有害气体和烟尘向地面扩散。当烟囱高度达50米以上时﹐烟囱顶部的风速为地面处风速的数倍。烟气到达地面时已在离烟囱很远的地方﹐这时烟气已在逐步扩散中稀释到无害的程度。对燃烧固体燃料的工业炉﹐在排烟系统中还要设置各种形式的除尘器﹐使烟气排出时的含尘浓度降低到200微克/米3以下。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条