1) spherical shell sector plate dimension

球壳板尺寸

1.

Author has described the existing problems in process of design,fabrication and installation for 5 000 m3 PVC spherical tank;discussed the problems and its solution for analysis design;design change for spherical shell sector plate dimension;weld gap exceeding the standard requirement etc.

叙述了5 000 m3氯乙烯球罐在设计、制造和安装过程中出现的问题;论述了关于球罐分析设计、球壳板尺寸设计变更、焊缝间隙超标等问题的原因和解决办法;针对球壳板制造和组装过程中出现的纵、环缝间隙问题,提出了调整安装形式的改进措施。

2) shell dimension

壳体尺寸

3) enclosure size

外壳尺寸

4) spherulite size

球晶尺寸

1.

The mechanical properties,spherulite size,melting point and crystallinity of the anhydrite/PP composites and the anhydrite modified by modifer/PP composites were studied.

研究了硬石膏及其表面改性对聚丙烯(PP)复合材料的力学性能、球晶尺寸、熔点和结晶度的影响。

2.

At the same time,MB could decrease the spherulite size and the crystallization degree of polypropylene.

结果表明,成核剂MB较好地改善了聚丙烯的力学性能以及熔体流动性能,降低了聚丙烯球晶尺寸。

3.

The morphologies of nonisothermal crystallized isotactic polypropylene (IPP)and added 25 nucleating agents samples have been studied by PLM and SEM The effect of nucleating agents and cooling rates (A) on spherulite size (d) has been researched.

研究了IPP及其加25种成核剂时的非等温结晶形态,考查了成核剂和线性降温速率α对球晶尺寸d的影响。

5) ball size

钢球尺寸

1.

From the analysis on factors of impacting ball size,it is indicates that several impacting factors such as experienced formula or semi-theoretical formula have been comprehensively considered and the design for ball size has been conducted,thus the precise value gained.

从分析影响钢球尺寸的因素出发 ,指出运用综合考虑了多个影响因素的经验公式或半理论公式 ,对钢球尺寸进行设计 ,方能获得其准确值。

2.

Based on the ball size that was calculated to meet the requirement for lab test, a series of orthogonal tests were carried out to select parameters appropriate to the ball milling process.

研究了球磨参数对NiFe2O4尖晶石粉料的颗粒粒径的影响·通过计算确定了试验所需钢球尺寸,在此基础上,进行正交试验选择合适的参数·试验结果表明,球磨时间是影响粒径的主要因素,而研磨体级配对粒径分布范围有较大影响·确定合适的球磨参数为:球磨时间36h;研磨体级配35∶40∶25;料球比1∶2;球磨介质的体积分数为75%

6) ball size

磨球尺寸

1.

Research on influences of ball size on the critical speed of small ball mills

磨球尺寸对小型球磨机临界转速影响的研究

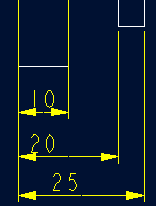

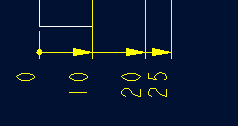

补充资料:工程图标准尺寸及坐标尺寸

标准标注类型,是我们常用的标注类型。而坐标标注是便于数控加工采用的另一中标注形式。PRO/E可以将两种标注方式进行转换。

· 3.2 标准标注到坐标标注的转换

注意: 转化为坐标标注的尺寸必须是线性标注的,下列尺寸不能转化为坐标标注:

- 被显示成线性尺寸的直径

- 中心线尺寸

- 选择MODIFY DRAW > Dim Params > Dim Type > Ordinate Dim > Create Base.

- 选择作为参考基准线的尺寸

- 选择基准的引出线,该点为0点

- 选择 MOD DIM TYPE > Lin to Ord .

- 选择线性尺寸:注意:必须选择具有相同基准的尺寸

========>>>>

========>>>>

1. 选择 DIM PARAMS > Diam Dim Type .

2.点击Ord to Lin

3.选择尺寸即可

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条