1) technology of dehydrated vegetables

蔬菜脱水技术

2) dehydrated vegetable

脱水蔬菜

1.

Application of Lactose in the dehydrated vegetable;

乳糖在脱水蔬菜加工中的应用

2.

Prime report of the application of heat pump dehydrating technology in dehydrated vegetable processing;

热泵干燥技术在脱水蔬菜加工中的应用研究

3.

Energy-saving reform of inner re-circulating pump drier for dehydrated vegetables

脱水蔬菜内循环式热泵干燥设备节能研究

3) dehydrated vegetables

脱水蔬菜

1.

Combination dryer of heat-pump and hot-air for drying of dehydrated vegetables

脱水蔬菜热泵-热风组合干燥装置设计

2.

The number of microorganisms in dehydrated vegetables (carrot, cabbage and bean sprout) could be effectively reduced using 60 Co γ radialization treatment and the preservation period could be prolonged to more than one year.

利用 6 0 Co- γ射线辐照处理脱水蔬菜 (胡萝卜、青梗菜、豆芽菜 ) ,能有效地杀灭产品中的微生物 ,贮藏保鲜效果在一年以上。

3.

The sterilization and preservation by radiation for dehydrated vegetables got good results.

脱水蔬菜辐照杀菌保藏效果显著。

5) dryer for vegetables

蔬菜脱水机

1.

Because each drying far Infrared dryer for vegetables oven directed the wind by the identical string stream,each box in vivo air flow was equal.

现有的远红外蔬菜脱水机各层干燥箱均由同一台风机串流引风,因此各层箱体内的空气流量相等。

6) dehydrated vagetable paper

脱水蔬菜纸

1.

In this article,the prodtiction technology and development prospects of thedehydrated vagetable paper are emphatically presented,and the technology parameter and mi-cowave-dry technique are studied,the quanity standard of the dehydrated vagetable paper israised.

本文介绍了脱水蔬菜纸的生产工艺及发展前景,并对工艺多数及采用微波干燥进行了研究,提出了脱水蔬菜纸的产品质量标准。

补充资料:DWT系列脱水蔬菜干燥机

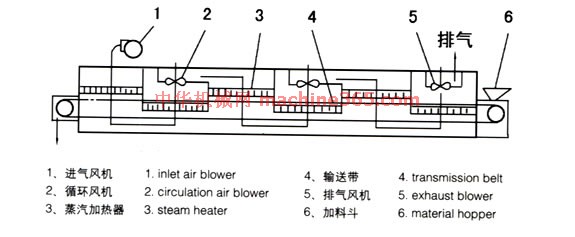

原理:

原理如图所示,料斗中的物料由加料器(6)均匀地铺在不锈钢丝网(4)上,由传动电机带动网在干燥箱内匀速移动。干燥段由若干单元组成,热风在两个或两个(或几个)单元内横向循环,新鲜空气由风机(1)进入,通过换热器(3)加热,热空气穿过物料民物料热交换,进入下腔,然后流向下一单元,降温后的热空气再经换热器(3)进行二次加热,热空气穿透网带与物料再次热交换,湿热空气由排湿风机(5)排出,完成干燥,每台干燥机单元数可根据物料的特性、工艺要求选取。

应用:

DWF系列带式干燥机是成批生产用的连续式干燥设备,用于透气性较好的片状、条状、颗粒状物料的干燥,对于脱水蔬菜、中药饮片等含水率高、而物料温度不允许高的物料尤为合适该系列干燥机具有干燥速度快、蒸发强度高、产品质量好的优点,对脱水滤饼类的膏状物料,需经造粒制成棒状后亦可干燥。

结构简图:

技术参数:

型号 | DWF-1.2-8 | DWF-1.2-10 | DWF-1.6-8 | DWF-1.6-10 | DWF-2-8 | DWF-2-10 |

单元数 | 4 | 5 | 4 | 5 | 4 | 5 |

带宽(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

干燥段长(m) | 8 | 10 | 8 | 10 | 8 | 10 |

铺料厚(mm) | 10~80 | |||||

使用温度(℃) | 60~150 | |||||

蒸汽压力(Mpa) | 0.2~0.8 | |||||

蒸汽耗量(kg/h) | 120~300 | 150~375 | 150~375 | 170~740 | 180~500 | 225~600 |

干燥时间(h) | 0.2~1.2 | 0.25~1.5 | 0.2~1.2 | 0.25~1.5 | 0.2~1.2 | 0.25~1.5 |

干燥强度(kgH2O/h) | 60~160 | 80~220 | 75~220 | 95~250 | 100~260 | 120~300 |

风机总功率(kw) | 8.8 | 11 | 12 | 15 | 16 | 20 |

设备总功率(kw) | 10.1 | 12.3 | 13.3 | 16.3 | 17.3 | 21.3 |

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条