1) repacked driving method

传动方式改造

2) transformation way

改造方式

1.

Adopting different transformation ways,the result indicated that the way of wide-band fell was good,and the survival rate of broad-leaved trees was high,and the growth of young forest was fast,which was suitable for heliophilous trees,strong-heliophilous trees and neuter partial to heliophilous trees.

厦门城市森林中马尾松劣质林分比例大,采用不同改造方式试验表明:宽带采伐更新改造效果较好,阔叶树种造林成活率高,幼林生长比较快,适宜阳性、强阳性和中性偏阳树种。

3) driveshaft transformation

传动轴改造

4) transmission mode

传动方式

1.

This paper introduces the structure and principle of the vacuum vertical disc filter,describes advanced design concept and reasonable structure adopted in the vacuum vertical disc filter design,which are expected to solve the problem existing in the filter,such as agitation,load and upload of the filter plate,transmission mode,support and manufacture.

介绍真空立式圆盘过滤机的结构和工作原理,阐述了在114m2真空立式圆盘过滤机设计中所运用的先进设计理念和合理结构,以期解决目前过滤机存在的搅拌、滤板装卸、传动方式、支撑及制造等方面的问题。

5) driving mode

传动方式

1.

In the light of the problem that the lower production capacity of th e filter with post pallet has influence on the production, this paper analyzes o n several factors influencing the filtering efficiency of the filter with post p allet from aspects of the structure of the post pallet, mixing mode, unloading m ode, driving mode, and the selection of filter cloth, etc.

针对立盘过滤机产能低影响生产的问题,主要从立盘结构、搅拌方式、卸料方式、传动方式及滤布选用等几方面进行了深入探讨,分析了影响立盘过滤机过滤效率的几种因素,提出了相应的改进措施;对正处于试验期间的一台立盘过滤机改造效果进行了分析,并对改造后的经济效益进行了预测。

6) drive mode

传动方式

1.

Concrete reforming technique is consisted of changing the drive mode of tooth roll from oscillatory mode to ro.

济钢球团厂齿辊卸料器存在着齿辊寿命短、鼓风机效率低、动静块密封不可靠且维修量大、液压系统故障多等缺陷,结合工艺要求对齿辊卸料器进行改进,将齿辊传动方式由摆式改为旋转式,增大动、静辊之间的排料间隙,将动静密封改为填料密封,并改造液压系统、水系统,从而提高了设备作业率,减少了设备维护,年增效益40。

2.

This article is intended for looper as critical device coupled to PL-TCM,and provides drive mode and power calculation method.

提出了联机活套的传动方式和功率计算方法。

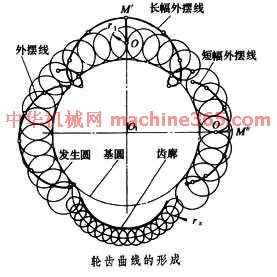

补充资料:传动:摆线针轮传动

由外齿轮齿廓为变态摆线﹑内齿轮轮齿为圆销的一对内嚙合齿轮和输出机构所组成的行星齿轮传动。除齿轮的齿廓外﹐其他结构与少齿差行星齿轮传动相同。摆线针轮行星减速器的传动比约为6~87﹐效率一般为0.9~0.94。图 轮齿曲线的形成 为轮齿曲线的形成原理。发生圆在基圆上滚动﹐若

大於r1﹐M'点画出的是长幅外摆线﹔若

大於r1﹐M'点画出的是长幅外摆线﹔若 小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条