1) optimum drive angle

最优传动角

1.

Give a way of designing the plane crank-rocker mechanism by the coefficient of stoke ratio K and optimum drive angle.

将图解法原理与解析手段有机结合,给出一种同时按K和最优传动角设计平面曲柄摇杆机构的方法。

2.

On the premise of satisfying the given rocker angle of oscillation and the coefficient of stoke speed ratio K, the mechanism can make a optimization design with the halp of a computer and conveniently get the Plane crank-rocker mechanism of the optimum drive angle.

在满足给定的摇杆摆角和行程速比系数K的前提下 ,借助计算机进行寻优设计 ,方便地求得具有最优传动角的平面曲柄摇杆机构。

2) minimum transmission angle

最小传动角

1.

Position analysis of minimum transmission angle of idle stroke in crank-rocker mechanism;

曲柄摇杆机构慢行程最小传动角位置分析

2.

Analytical method for designing crank-rocker mechanism according to minimum transmission angle;

按最小传动角设计曲柄摇杆机构的解析方法

3.

This paper is disscussing a new method which is used to determine the position and dimension of minimum transmission angle of plane Crank-and-Rocker mechanism with Time Ration(k=1&k≠1).

阐述了确定行程速比系数和的平面曲柄摇杆机构最小传动角位置和大小的新方法。

3) the minimum transmission angle

最小传动角

1.

The article bases on the traditional graphical method,and applies design principle in the references[1],derives the optimizing design methods which under the condition of meeting the fixed slider stroke and the coefficient of variety of stroke velocity,makes the minimum transmission angle of the eccentric crank slider mechanism to maximum(that is the best transmission angle).

在传统图解法的基础上,运用文献[1]中的设计原理,推导出在满足给定的滑块行程和行程速度变化系数的条件下,使偏置曲柄滑块机构的最小传动角达到最大(最佳传动角)的优化设计方法。

4) minimum driving angle

最小传动角

1.

According to its equivalent mechanism—crank rocker mechanism, driving performance and minimum driving angle position of movable tooth is analyzed.

利用摆动活齿传动等效机构,分析其传动性能和最小传动角的位置。

2.

Given the stroke speed ratio factor K of the quadric crank mechanism and the position of the two poles of the actuating driven member, using the minimum driving angle as the objective, the type and size of the quadric crank mechanism are determined with optimistic technology.

已知曲柄四杆机构的行程速比系数 K及执行从动件动点的两极限位置 ,采用最优化技术 ,以机构最小传动角最大作为寻优目标函数 ,确定曲柄四杆的类型及其尺寸。

3.

With the assistance of computer coded program, this paper, by means of geographically analysing crank and rocker mechanism, helps readers to find out a center point, at which the biggest minimum driving angle is.

通过对图解法设计曲柄摇杆机械的几何分析 ,用计算机编程设计找到使机构最小传动角最大的曲柄回转中心 ,达到优化设计机构的目

6) the maximum of the minimum transmission angle

最小传动角的最大值

补充资料:传动:摆线针轮传动

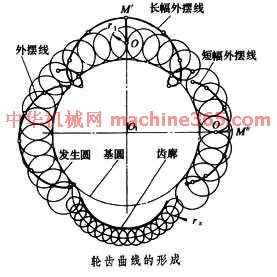

由外齿轮齿廓为变态摆线﹑内齿轮轮齿为圆销的一对内嚙合齿轮和输出机构所组成的行星齿轮传动。除齿轮的齿廓外﹐其他结构与少齿差行星齿轮传动相同。摆线针轮行星减速器的传动比约为6~87﹐效率一般为0.9~0.94。图 轮齿曲线的形成 为轮齿曲线的形成原理。发生圆在基圆上滚动﹐若

大於r1﹐M'点画出的是长幅外摆线﹔若

大於r1﹐M'点画出的是长幅外摆线﹔若 小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条