1) little-tooth number gear mechanism

少齿数齿轮机构

3) little teeth number gear-pair s

少齿数齿轮副

4) gear mechanism

齿轮机构

1.

The traditional theory of involute gear transmission considers that the tooth profiles of gear mechanism are uniformly wore along tooth surface during the operating, and the worn tooth profiles can still keep the original involute shape.

传统的渐开线齿轮传动理论认为 :齿轮机构运行时轮齿沿齿面均匀磨损 ,磨损后的齿廓仍可保持原渐开线形状。

2.

The CAI software presented in this paper,which is composed of a lot of slides deding with teaching contents on four bars mechanism,cam mechanism and gear mechanism was constructed with PowerPiont97 software.

主控模块下设置三个子工程,即四杆机构、凸轮机构和齿轮机构;各个模块下各自分别挂 接教学模块和练习模块两个下级模块 。

3.

lt is incomplete to caculate the freedom of plane gear mechanism regarding gearpair as higher pair.

指出将齿轮副作为高副来计算平面齿轮机构自由度是不全面的。

5) gearing

[英]['ɡɪərɪŋ] [美]['gɪrɪŋ]

齿轮机构

1.

Even if the input torque of an involute gearing keeps constant, the output torque of its driven gear surely fluctuates to a certain extent due to the existence of the sliding friction between teeth.

研究表明 ,齿间摩擦的存在会使渐开线齿轮机构输出扭矩产生一定的波动[1,2 ] 。

2.

The classical involute gearing theory, which omits the effect of sliding frictions between teeth and between bearings and journals, thinks that if the input torque of the gearing is kept constant the gears do not vibrate .

不计齿间及轴颈与轴承间摩擦的经典渐开线齿轮理论认为,若输入扭矩保持恒定,则齿轮机构运行平稳,不会振动。

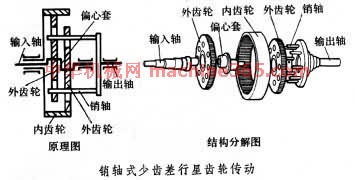

补充资料:传动:少齿差行星齿轮传动

由一对齿数相差很少的内嚙合齿轮和输出机构组成的行星齿轮传动。通常齿数差为1~4。外齿轮通过轴承和偏心套装在减速器的输入轴上(见图 销轴式少齿差行星齿轮传动  )。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

)。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条