1) double-chain steam boiler

双炉排链条锅炉

2) chain-boiler

链条锅炉

1.

The effect and process scheme for combustion of chain-boiler when the quality of coal changed;

煤质变化对链条锅炉燃烧影响及处理方案

3) chain grate boiler

链条锅炉

1.

Comprehensive reconstruction of chain grate boiler for energy saving and consumption reduction

链条锅炉节能降耗综合改造

2.

In consideration of the very frequent load fluctuations of chain grate boilers with a steam capacity of 10 t/h and lower a dynamic mathematical model was set up by using a modular modeling method for the steam-water system and combustion system of a 10 t/h chain grate boiler.

针对10 t/h及以下容量链条锅炉负荷的频繁波动,采用模块化的建模方式建立了一台10 t/h链条锅炉的汽水系统和燃烧系统的动态数学模型,并进行了仿真试验,得到炉排速度和空气量发生变化时锅炉燃烧率、蒸汽流量、过热汽温和汽包水位的实时变化量和趋势。

3.

Imperfections that appear in stratified combustion of chain grate boilers have successfully been dealt with, to raise the boilers output and efficiency and also to alleviate contamination caused by smoke and dust.

对链条锅炉层燃中出现的弊病提出妥善处理意见 ,以提高锅炉出力和效率 ,减少烟尘污染。

4) chain boiler

链条锅炉

1.

New type loose coal equipment of chain boiler;

链条锅炉的新型松煤装置

2.

Application Of Pulverized coal combustion technology in chain boiler

煤粉燃烧技术在链条锅炉中的应用

3.

This article introduces several measures of improving the heat transfer path of the chain boiler, and points out that the reasonable distribution arrangement of the heated surface, preventing fume to short circuit, keeping clean the heated surface and the adding tail heated surface could improve the thermal efficiency so as to obtain obvious result of energy saving.

介绍了改善链条锅炉本身传热途径的几种措施 ,即从受热面的合理分配布置 ,防止烟气短路 ,保持受热面内外部洁净 ,加装尾部受热面入手来提高锅炉热效率 ,节能效果明

5) chain bolier

链条锅炉

1.

It is ameliorated to equipment of chain bolier supply coal by the technology of delamination burnt, the coal burnt on stove row delamination burnt, coal powder become suspend sate in the boier, it make the coal burnt completeness, so reduce the contain carbon of slag, that improve thermal efficiency of the boiler, it is a way to reduce energy consumption.

利用分层燃烧技术对链条锅炉给煤装置进行改造,使煤在炉排上分层燃烧,是使煤燃烧完全,降低出渣含碳量,提高锅炉热效率,降低能源消耗的有效途径。

6) chain-grate boiler

链条锅炉

1.

A discussion is made on the technical renovation in the fields of arch structure, heat-resistant mat reinforcement, refractory of both arch and roof, and fixed mode of shelf rest for skimmer in the coal-fired chain-grate boiler with evaporation capacity of 35t/h.

对蒸发量为35t/h的燃煤链条锅炉的炉拱结构、耐热钢筋网,炉拱、炉顶耐火材料,挡渣器搁座的固定方式的技术改造进行了探讨。

2.

Due to very low efficiency and low-level automation of most of current domestic chain-grate boiler, an advanced energy-saving automatic control and supervisory system suitable for chain-grate boiler was developed.

链条锅炉是重要的工业民用设备,针对大多数链条锅炉效率和自动化水平低下的现状,研制了一种适于链条锅炉的先进的节能自动监控系统。

3.

Comparing with CFB boiler, the chain-grate boiler with lower thermal efficiency (50%~60%), higher unit coal consumption(more than 180 kg/tce)and lower draw-off rate(about 70%) can\'t meet the requirements of the energy conservation and environmental protection.

同CFB锅炉相比,链条锅炉热效率低(50%~60%)、煤单耗高(标煤180kg/t以上)、出汽率低(70%左右),不能满足节能和环保的要求。

补充资料:工业炉:工业炉排烟系统

利用烟囱或机械装置将工业炉炉膛内的烟气排出炉外的系统。保证排烟通畅是工业炉正常使用的重要条件﹐排烟不通畅时﹐炉膛压力昇高﹐从炉膛四周的缝隙会逸出大量烟气而增加炉子的热损失﹐影响炉内气流的均匀分布﹐降低炉温均匀性﹐恶化操作环境。

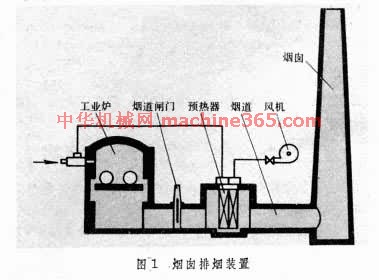

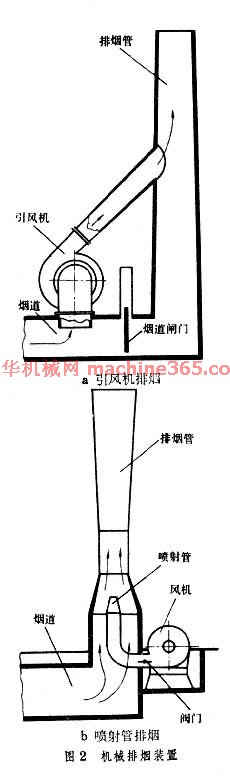

排烟系统是由產生抽力的排烟装置和排送烟气的烟道所组成。常用的排烟装置有烟囱(图1 烟囱排烟装置  )﹑引风机或喷射管(图2 机械排烟装置

)﹑引风机或喷射管(图2 机械排烟装置  )等。

)等。

烟囱排烟是靠流入烟囱内热烟气密度小於烟囱外空气密度所產生的浮力﹐以克服烟道的阻力。利用引风机也可将烟气排出﹐或在排烟系统中某一部位装设一个喷射管﹐用高速喷射气体所產生的负压排出烟气。烟囱排烟不消耗动力﹐排烟温度不受限制。当排烟阻力很大而工业炉又间断运行时﹐可用引风机或喷射管排烟。喷射管适用於排除高温烟气﹔引风机适用於排除低温烟气。

烟囱分为砖砌烟囱﹑混凝土烟囱和钢板烟囱。烟道有地下烟道和架空烟道两种。地下烟道多用砖砌﹐架空烟道宜採用衬有耐火材料的钢板製成。

为了减少烟气对环境的污染﹐或因节能需要而在烟道内设置预热器时﹐都需要儘量提高烟囱高度并增加烟囱出口处的烟气流速﹐使之大於当地最大风速或至少不低於3米/秒﹐以避免烟气中的有害气体和烟尘向地面扩散。当烟囱高度达50米以上时﹐烟囱顶部的风速为地面处风速的数倍。烟气到达地面时已在离烟囱很远的地方﹐这时烟气已在逐步扩散中稀释到无害的程度。对燃烧固体燃料的工业炉﹐在排烟系统中还要设置各种形式的除尘器﹐使烟气排出时的含尘浓度降低到200微克/米3以下。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条