1) allowable transmission angle

许用传动角

1.

Based on the "Auxiliary Angle Method", this paper puts forward and solves the theoretical task for designing planar crank and slider mechanism with allowable transmission angle and most evident Quick-return Characteristics K max .

以“辅助角方法”为理论基础 ,提出并解决了按一并具有许用传动角 [γ]和最显著急回特性Kmax之条件设计平面曲柄滑块机构的理论课题 。

2.

In this paper, an analytical method for designing a crank\|and\|rocker mechanism using a Time Ratio ( K ), a swing angle of the rocker ( ψ ) and an allowable transmission angle () as basic parameters is given.

给出了按行程速比因数、摇杆摆角和许用传动角作为基本参数设计曲柄摇杆机构的解析法 。

3.

This paper makes deep and systematic researches on the theoretical task according to travel velocity-ratio coefficient K and allowable transmission angle,and draws some conclusions of guiding significance for the analysis and synthesis of type Ⅰ as well as type Ⅱ planar crank and rocker mechanisms.

对兼按行程速比系数K和许用传动角 [γ]设计平面曲柄摇杆机构的理论课题进行了系统的讨论 ,得到了若干对Ⅰ型、Ⅱ型平面曲柄摇杆机构分析与设计有关的结

2) mechanismpermitted transmission angle

机构许用传动角

3) allowable pressure angle

许用压力角

1.

Analytical method for designing the crank-slider mechanism according to allowable pressure angle,cofficient of stroke speed ratio and stroke;

根据许用压力角、行程速比系数和行程设计曲柄滑块机构的解析法

2.

A mathematical model was proposed to analyze the pressure distributions of a straight line moving disk cam mechanism and it was found that the allowable pressure angle was related to the material type, frictional condition, service load and the instantaneous acceleration speed of the driven part.

通过建立力学模型 ,对直动盘状凸轮机构进行了受力分析 ,指出凸轮压力角引用传统方法 ,即单一升程、回程许用压力角 [α1]=30°,[α2 ]=70°~ 80°,不合理。

3.

Aimed at the problem of determining fundamental dimensions of planar cam mechanisms, the analytical formula of calculating fundamental dimensions of mechanisms in accordance with allowable pressure angle are deduced from the combination of the extreme comditions with the expressions of pressure angle.

对于平面凸轮机构基本尺寸的确定问题,本文用机构压力角相对于凸轮转角的极值条件,与机构的压力角表达式相联立,导出了根据许用压力角确定机构基本尺寸的解析算式。

4) allowed pressure angle

许用压力角

1.

Determination of the basic size of cam mechanism with oscillating follower based on the allowed pressure angle;

按许用压力角确定摆杆盘形凸轮基本尺寸

2.

The result shows that when follower pertains to ordinary and 3 order polynomial motion rule,with the allowed pressure angle being given,the basic circle radius and eccentricity of cam mechanism can be defined,so the presented method is easier in comparison with others.

只要从动件为常用的运动规律以及不超过3次的多项式运动规律,在满足许用压力角的前提下,采用该解析法确定凸轮基圆半径和偏距,比其它解析法简捷方便。

3.

According to the allowed pressure angle, this paper determines the disk cam with translating follower s basic circle radius and eccentricity by using the analytic method.

本文尝试采用解析法,按许用压力角确定直动从动件盘形凸轮机构的基圆半径和偏心距。

5) Permitted booster

许用传爆药

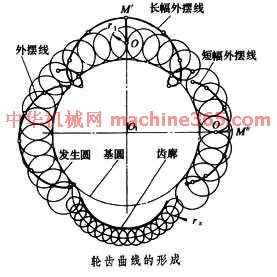

补充资料:传动:摆线针轮传动

由外齿轮齿廓为变态摆线﹑内齿轮轮齿为圆销的一对内嚙合齿轮和输出机构所组成的行星齿轮传动。除齿轮的齿廓外﹐其他结构与少齿差行星齿轮传动相同。摆线针轮行星减速器的传动比约为6~87﹐效率一般为0.9~0.94。图 轮齿曲线的形成 为轮齿曲线的形成原理。发生圆在基圆上滚动﹐若

大於r1﹐M'点画出的是长幅外摆线﹔若

大於r1﹐M'点画出的是长幅外摆线﹔若 小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

小於r1﹐M''点画出的是短幅外摆线﹔用这些摆线中一根曲线上的任意点作为圆心﹐以针齿半径rz为半径画一系列圆﹐而后作一根与这一系列圆相切的曲线﹐得到的就是相应的长幅外摆线齿廓或短幅外摆线齿廓﹐其中短幅外摆线齿廓应用最广。用整条短幅外摆线作齿廓时﹐针轮和摆线轮的齿数差仅为1﹐而且理论上针轮有一半的齿数都与摆线轮齿同时嚙合传动。但如果用部分曲线为齿廓就可得到两齿差和三齿差的摆线针轮传动。用长幅外摆线的一部分作轮齿曲线时﹐其齿廓与圆近似﹐并与针齿半径相差不大﹐因此可用它的密切圆弧代替。摆线针轮传动的优点是传动比大﹑结构紧凑﹑效率高﹑运转平稳和寿命长。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条