1) low temperature economizer

低温省煤器

1.

Analysis and policies for the leakage of low temperature economizer in coal-fired boiler;

煤粉锅炉低温省煤器泄漏的原因分析及对策

2.

Recently, Guangzhou Yuancun Cogeneration Power Plant s boilers incurred quite a number of failures, caused by water leakage of low temperature economizers.

广州员村热电有限公司锅炉近期发生多起低温省煤器漏水事故。

3.

To make more use of heat energy in the flue gas, a new type of low temperature economizer (LTE) is put forward.

为进一步利用锅炉的排烟热量,提出了一种新型低温省煤器。

2) low temperature coal saver

低温省煤器

1.

The utilization of a new type of low temperature coal saver in power station s boilers;

用于电站锅炉的新型低温省煤器

3) low-pressure economizer

低压省煤器

1.

The low-pressure economizer installed in thermal system of power stations gives a useful option for reducing the coal consumption rate .

在电厂的热系统内增设低压省煤器是降低发电标准煤耗的有效措施。

2.

Additionally installing low-pressure economizer in the thermodynamic system of thermal power plants is one of the effective measures to lower the temperature of exhaust flue gas for energy-saving.

在电厂热系统中增设低压省煤器是降低排烟温度节约能源的有效措施之一。

4) low pressure economizer

低压省煤器

1.

Practice of low pressure economizer installed in 670 t/h coal-fired boiler to reduce the exhaust gas temperature;

670t/h锅炉增设低压省煤器降低排烟温度的实践

2.

Through a series of technical retrofit such as high and low pressure cylinder of steam turbine, condenser, boiler air pre-heater, low pressure economizer, pump and fan, the power consumption of main equipments and subsidiary motors was decreased.

通过对汽轮机高低压缸通流部分、凝汽器、锅炉空气预热器密封、锅炉尾部加装低压省煤器、泵与风机等一系列技术改造后,主设备能耗和辅机电耗都有明显下降。

3.

This paper describes the application of optimization technology in the design of low pressure economizer fixed with fined tubes in Shandong Weihai power station,and discuses the stability of the optimum parameters.

文中叙述了最优化技术在山东华能威海电厂螺旋肋片管低压省煤器设计中的应用 ,并对最优参数的稳定性进行了分

5) high-temperature economizer

高温省煤器

6) cold-end element

冷端元件,低温元件(如省煤器,预热器)

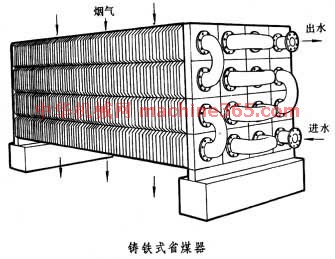

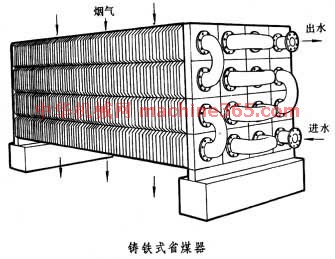

补充资料:动力机械: 省煤器

布置在锅炉尾部烟道内加热给水的部件。它的作用是吸收锅炉尾部烟气中的部分热量﹐降低排烟温度﹐以节省燃料。现代锅炉一般都有省煤器。省煤器一词来源于燃煤锅炉﹐对于燃油﹑气和其它燃料的锅炉习惯上也称为省煤器。省煤器按出口水是否汽化分为沸腾式和非沸腾式。沸腾式的省煤器的沸腾率(出口水中汽化部分的质量百分数)不应超过20%﹐过大会增加流动阻力﹐甚至会出现管组中各管流量交替脉动﹐使省煤器振动﹐从而造成损坏。中压锅炉的省煤器常为沸腾式﹐其它压力的锅炉则常为非沸腾式。省煤器按结构和材料又可分为铸铁式和钢管式。铸铁式省煤器(见图 铸铁式省煤器 )强度不高﹐用于压力小于2.5兆帕的锅炉。为了加强传热﹐管外有大量鳍片。铸铁式省煤器承受振动和冲击的能力较差﹐故不能用作沸腾式﹔但耐腐蚀性能良好﹐可用于给水未经除氧的工业锅炉。钢管式省煤器不受压力限制﹐可以用作沸腾式﹐一般由外径为32~51毫米的碳素钢管制成。有时在管外加鳍片和肋片﹐以改善传热效果。钢管式省煤器由水平布置的并联弯头管子(习称蛇形管)组成。

)强度不高﹐用于压力小于2.5兆帕的锅炉。为了加强传热﹐管外有大量鳍片。铸铁式省煤器承受振动和冲击的能力较差﹐故不能用作沸腾式﹔但耐腐蚀性能良好﹐可用于给水未经除氧的工业锅炉。钢管式省煤器不受压力限制﹐可以用作沸腾式﹐一般由外径为32~51毫米的碳素钢管制成。有时在管外加鳍片和肋片﹐以改善传热效果。钢管式省煤器由水平布置的并联弯头管子(习称蛇形管)组成。

)强度不高﹐用于压力小于2.5兆帕的锅炉。为了加强传热﹐管外有大量鳍片。铸铁式省煤器承受振动和冲击的能力较差﹐故不能用作沸腾式﹔但耐腐蚀性能良好﹐可用于给水未经除氧的工业锅炉。钢管式省煤器不受压力限制﹐可以用作沸腾式﹐一般由外径为32~51毫米的碳素钢管制成。有时在管外加鳍片和肋片﹐以改善传热效果。钢管式省煤器由水平布置的并联弯头管子(习称蛇形管)组成。

)强度不高﹐用于压力小于2.5兆帕的锅炉。为了加强传热﹐管外有大量鳍片。铸铁式省煤器承受振动和冲击的能力较差﹐故不能用作沸腾式﹔但耐腐蚀性能良好﹐可用于给水未经除氧的工业锅炉。钢管式省煤器不受压力限制﹐可以用作沸腾式﹐一般由外径为32~51毫米的碳素钢管制成。有时在管外加鳍片和肋片﹐以改善传热效果。钢管式省煤器由水平布置的并联弯头管子(习称蛇形管)组成。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条