1) weld with several welders in equal speed

多焊工等速焊接

2) welder

[英]['weldə(r)] [美]['wɛldɚ]

焊接者 焊工

3) block welding technique

多层焊接工艺

4) welding speed

焊接速度

1.

Relation of welding speed and heat input at aluminum alloy friction stir welding

铝合金搅拌摩擦焊时焊接速度与热输入的关系

2.

The impact of different welding speeds on the low-cycle corrosion fatigue life of 12Cr18Ni10Ti steel sheets in corrosive media was studied and the results showed that,at the same welding process parameters,the low-cycle corrosion fatigue life of steel sheets welded at the speeds ranging from 60 m/hr.

文章研究了不同的焊接速度对12Cr18Ni10Ti薄板在腐蚀性介质中的低用腐蚀疲劳寿命的影响。

3.

The effect of processing parameters including laser power,welding speed and protection gas flow on the welding quality was researched in this paper.

探讨了焊接工艺参数包括激光功率、焊接速度、正反面保护气体流量对焊接效果的影响。

5) high-speed welding

高速焊接

1.

Improvement on high-speed welding technology of robot;

弧焊机器人高速焊接工艺改进

2.

The hardware/software configurations, organization and property of high-speed welding system and the technology of high-speed welding for profiled rolle steel was introduced in this paper.

介绍了多源钨极氩弧焊异型钢材高速焊接系统软 /硬件设计、构成、性能和高速焊接工艺 ,此系统在型材轧制生产线上得到了应

6) high speed welding

高速焊接

1.

The theory of stability of a liquid with free surface is applied to understand the ‘humping’ phenomenon in bead formation during high speed welding.

应用具有自由表面的流体稳定性理论,解释了高速焊接时驼峰焊道的产生机理,并通过对熔池形成过程的实时图像采集对该理论进行了验证。

2.

If the generation mechanism of weld bead defects is understood and some suppression measures are proposed, then some improvements can be made for conventional arc welding process so that low-cost and widely used high speed welding process is obtained.

如果针对常用的电弧焊,研究焊接速度提高时焊缝成形缺陷的形成机理,进而提出一定的抑制措施,在此基础上对常规电弧焊工艺做适当改进,得到一种成本低廉、可广泛推广的高速焊接工艺,对于大幅度提高焊接生产效率具有重要的理论意义和工程实用价值。

3.

And it is proved that hard arc is more stable under lower voltage,which is suitable for high speed welding.

在数字控制绝缘栅极晶体管逆变电源平台基础上,研究了短路过渡高速焊接工艺的参数匹配和波形控制规律。

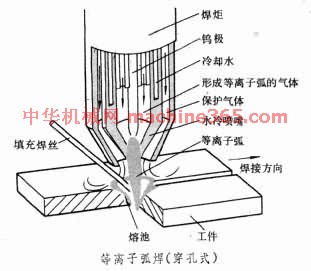

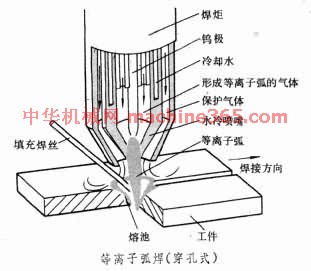

补充资料:焊接:等离子弧焊

利用等离子弧作为热源的焊接方法(见图 等离子弧焊(穿孔式)  )。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

)。气体由电弧加热產生离解﹐在高速通过水冷喷嘴时受到压缩﹐增大能量密度和离解度﹐形成等离子弧。它的稳定性﹑发热量和温度都高於一般电弧﹐因而具有较大的熔透力和焊接速度。形成等离子弧的气体和它周围的保护气体一般用氬。根据各种工件的材料性质﹐也有使用氦或氬氦﹑氬氢等混合气体的。等离子弧有两种工作方式。一种是“非转移弧”﹐电弧在钨极与喷嘴之间燃烧﹐主要用於等离子喷镀或加热非导电材料﹔另一种是“转移弧”﹐电弧由辅助电极高频引弧后﹐电弧燃烧在钨极与工件之间﹐用於焊接。形成焊缝的方式有熔透式和穿孔式两种。前一种形式的等离子弧只熔透母材﹐形成焊接熔池﹐多用於0.8~3毫米厚的板材焊接﹔后一种形式的等离子弧只熔穿板材﹐形成钥匙孔形的熔池﹐多用於 3~12毫米厚的板材焊接。此外﹐还有小电流的微束等离子弧焊﹐特别适合於0.02~1.5毫米的薄板焊接。等离子弧焊接属於高质量焊接方法。焊缝的深/宽比大﹐热影响区窄﹐工件变形小﹐可焊材料种类多。特别是脉衝电流等离子弧焊和熔化极等离子弧焊的发展﹐更扩大了等离子弧焊的使用范围。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条