1) plastic zone size atcrack tip

裂尖塑性区尺寸

2) CTPZ size

裂纹尖端塑性区尺寸

3) size of plastic zone

塑性区尺寸

1.

为了预测复合型裂纹呈滑移型(Ⅱ型)的断裂,在此提出了复合型裂纹扩展的最大塑性区尺寸断裂判据。

4) plastic zone size

塑性区尺寸

1.

The new analytical elements can be implemented into FEM program systems to compute the plastic zone sizes and crack tip opening or sliding displacement based on mode Ⅰ or mode Ⅱ D.

将该解析元与有限元相结合,构成半解析的有限元法,可求解任意几何形状和载荷的Ⅰ型或Ⅱ型裂纹基于Dugdale模型的裂纹尖端塑性区尺寸和裂纹尖端张开位移(CTOD)或裂纹尖端滑开位移(CTSD)的计算问题。

2.

In this paper, a method is proposed to estimate the plastic zone size, by extending the Dugdale model to three dimensional (3D) crack problems and the crack opening displacement (COD) at the tip of a sptatial penny shaped crack by combining the Barenblatt Dugdale model with the principle of 3D J integral, then the relationship between J integral and COD is obtained.

将Dugdale模型推广到三维裂纹问题计算了圆盘状裂纹前缘塑性区尺寸,并结合断裂力学中的Barenblat-Dugdale裂纹模型和三维J-积分原理计算了圆盘状裂纹前缘张开位移,得到了J-积分与裂纹张开位移的关系。

5) crack tip plastic zone

裂尖塑性区

1.

Fracture criterion for mixed mode crack of composites based on the crack tip plastic zone

基于裂尖塑性区的复合材料复合型裂纹断裂准则

2.

The unified solutions for the shape and size of mode I crack tip plastic zone are obtained based on the twin shear unified strength theory.

给出了包含反映材料拉压性能差异的参数拉压比及反映中间主应力效应的参数b的I型裂纹裂尖塑性区形状和大小的统一解。

3.

Then,by applying unified twin shear strength theory,the expansion angle and crack tip plastic zone of deep tunnel surrounding rock in rich water zone was studied,and the general solutions was obtained.

然后,采用双剪统一强度理论,研究了富水区巷道围岩微裂纹扩展角及裂纹尖端塑性区范围,并给出了包含反映岩石拉压性能差异的参数α、反映中间主应力效应的参数b及水压力的巷道围岩微裂纹裂尖塑性区统一解。

6) crack tip plastic zone

裂纹尖端塑性区

1.

Influence of fatigue crack tip plastic zone on crack propagation behavior in TC4ELI alloy

TC4ELI合金疲劳裂纹尖端塑性区对裂纹扩展的影响

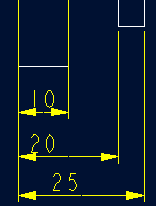

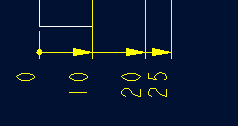

补充资料:工程图标准尺寸及坐标尺寸

标准标注类型,是我们常用的标注类型。而坐标标注是便于数控加工采用的另一中标注形式。PRO/E可以将两种标注方式进行转换。

· 3.2 标准标注到坐标标注的转换

注意: 转化为坐标标注的尺寸必须是线性标注的,下列尺寸不能转化为坐标标注:

- 被显示成线性尺寸的直径

- 中心线尺寸

- 选择MODIFY DRAW > Dim Params > Dim Type > Ordinate Dim > Create Base.

- 选择作为参考基准线的尺寸

- 选择基准的引出线,该点为0点

- 选择 MOD DIM TYPE > Lin to Ord .

- 选择线性尺寸:注意:必须选择具有相同基准的尺寸

========>>>>

========>>>>

1. 选择 DIM PARAMS > Diam Dim Type .

2.点击Ord to Lin

3.选择尺寸即可

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条