1) Super Stainless Steel

超级不锈钢

2) super 13Cr stainless steel

超级13Cr不锈钢

3) super duplex stainless steel

超级双相不锈钢

1.

The tensile properties at 900-1300℃,as well as the deformed microstructure of the as-forged 00Cr25Ni7Mo4N super duplex stainless steel(SDSS)have been studied by thermo-mechanical simulator.

用Gleeble-3800热变形模拟试验机研究了锻态00Cr25Ni7Mo4N超级双相不锈钢在900~1300℃时的高温拉伸塑性和高温变形组织特征。

2.

The effect of the heat treatment on the dual phase scale and corrosion property of the super duplex stainless steel 00Cr25Ni7MoN have been introduced in this article.

本文介绍了热处理工艺对超级双相不锈钢00Cr25N i7Mo4N中两相的比例有影响,进而对该钢的耐腐蚀性能也造成影响的试验分析情况。

3.

The influence of rare earths on solidification structure of 00Cr25Ni7Mo4N super duplex stainless steel was studied.

研究了Ce对00Cr25Ni7Mo4N超级双相不锈钢凝固组织的影响,结果表明,随着钢中Ce含量的增加,其凝固组织中等轴晶线性比相应明显增加,Ce含量为0%,0。

4) super austenitic stainless steel

超级奥氏体不锈钢

1.

The concept of super austenitic stainless steel appeared with super ferrite stainless steel and super double phases stainless steel together.

超级奥氏体不锈钢的概念是与超级铁素体不锈钢及超级双相不锈钢一起出现的。

2.

The liquids of N08904 super austenitic stainless steel was computed and tested by means of theoretical calculation and thermal analysis,reasonable overheat was put forward and leaking problem of molten steel during continuous casting was solved and continuous casting production had come into effect.

采用理论计算与热分析相结合的方式对N08904超级奥氏体不锈钢的液相线温度进行了计算测试,提出了合理的过热度参数,解决了连铸易漏钢问题,实现了连铸生产。

3.

The results showed that Cr20Ni18Mo6MnVSi super austenitic stainless steel in the chloride solution had excellent corrosion resistance properties after solution treatment at 1100℃ for 2h and followed by the aging treatment at 520℃ for 4h.

1型超级奥氏体不锈钢经1100℃固溶2h+520℃时效4h处理后,在高浓度氯离子溶液中的耐腐蚀性能优异。

5) Super Duplex Stainless Steel 00Cr25Ni7Mo4N

超级双相不锈钢00Cr25Ni7Mo4N

1.

Influence of Solution Temperature on Structure and Properties of Super Duplex Stainless Steel 00Cr25Ni7Mo4N;

固溶温度对超级双相不锈钢00Cr25Ni7Mo4N组织和性能的影响

6) cast super duplex stainless steel

铸造超级双相不锈钢

1.

In this paper,the effects of aging treatments on the type,size and quantity of precipitation particles of a cast super duplex stainless steel after solution treatment were studied by means of OM,SEM,XRD and TEM.

对固溶处理后的铸造超级双相不锈钢材料进行时效处理,利用OM,SEM,XRD和TEM分析了时效温度对析出相的影响。

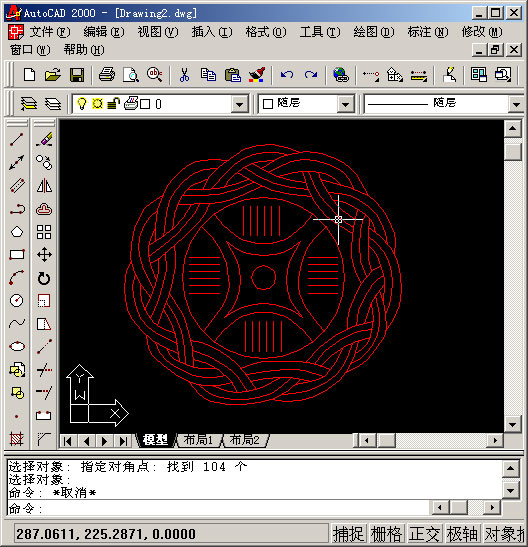

补充资料:AutoCAD 超级填充用法

在使用超级填充前首先要确认你的ACAD已经安装了快捷工具

1、画好填充内容,做成块,本例的块名是“h1”

1、画好填充内容,做成块,本例的块名是“h1”

2、用superhatch,并根据实际情况选择填充参数

以下是我的命令行提示,除了比例需要自己输入,其他只要用鼠标点点就行

命令: superhatch

AutoCAD Express Tools Copyright ?1999 Autodesk, Inc.

正在初始化...

H1 指定插入点或 [比例(S)/X/Y/Z/旋转(R)/预览比例(PS)/PX/PY/PZ/预览旋转(PR)]:

输入 X 比例因子,指定对角点,或者 [角点(C)/XYZ] <1>: .1

输入 Y 比例因子或 <使用 X 比例因子>: .1

指定旋转角度 <0>:

命令:

接受该 BLOCK 的位置吗? [是(Y)/否(N)] <是>:

指定矩形的圆角半径 <0.0000>:

指定矩形的线宽 <0.0000>:

指定矩形的厚度 <0.0000>:

在 block 周围选择一个窗口来定义列和行的距离。

当前矩形模式: 宽度=0.8207

指定 block 的第一个角点 [范围(E)] <紫色矩形>:

当前矩形模式: 宽度=0.8207

指定矩形的圆角半径 <0.0000>:

指定矩形的线宽 <0.8207>:

指定矩形的厚度 <0.0000>:

正在选择用于边界检测的可见对象...完成。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条