1) fused lump

结炉

1.

Based on eight times fused lump accident occurred in № 1 shaft furnace of NANGANG pelletizing plant in between June 1997 to march 1998,the mechanism and reason of fused lump in shaft furnace were analyed Some effective measures were proposed and adopted, these were avaiable for other pelletizing shaft furnace referenc

针对南钢 1号球团竖炉自 1997年 6月到 1998年 3月间发生的 8次结块结炉事故 ,分析了结块机理和该厂发生结炉的原因 ,并提出了有效的预防措施 ,可供同类型球团厂参

2) Slag and liner

炉结炉衬

3) furnace structure

炉型结构

4) sintering furnace

烧结炉

1.

The bit-sintering furnace automatic controlled by EIP;

嵌入式电脑自动控制钻头烧结炉

2.

Design of wireless monitor system based on nRF401 for sintering furnace;

基于nRF401的烧结炉无线监控系统的设计

3.

Design of temperature control system for small diameter saw blade sintering furnace based on S7-200 PLC

基于S7-200 PLC的小锯片连续烧结炉温度控制系统的设计

6) hearth chill

炉缸冻结

1.

Cause and handling of hearth chill in the No.5 BF at SISG;

韶钢5号高炉炉缸冻结事故的原因及处理

2.

Through adopting the technical measures such as local tuyere blowing above iron notch, burning iron notch with rich oxygen lance, tapping from iron notch, discharging slag and hot metal timely, adding coke in concentrative and de-concentrative forms and drilling the tuyere timely and so on, the accident of hearth chill was treated effectively.

通过采取铁口上方局部风口送风、富氧枪烧铁口、铁口出铁、及时排放渣铁、集中与分散加焦和适时打风口等措施 ,有效地处理了炉缸冻结事

3.

The process of hearth chill in blast furnace No.

简述了萍钢 30 1号高炉炉缸冻结的经过及处理过程 ,分析了炉缸冻结的原因 ,总结了本次炉缸冻结及处理的经验与教训。

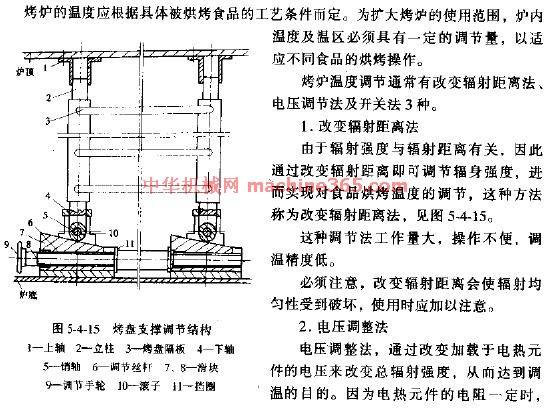

补充资料:带式饼干烤炉的结构——炉温调节装置

| ||

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条