1) leakage on the end-cover

端盖漏料

1.

This paper introduces the harms of the leakage on the end- cover of grate mill, analyzes on its causes, and puts forward some corresponding measures and methods for control.

介绍了格子磨端盖漏料的危害,分析了端盖漏料的原因,提出了相应的治理措施与方法。

2) Cancellation Missed

漏盖

3) End cover

端盖

1.

Regarding the ball mill as a rotary body being composed of end covers and barrel shell, a finite element calculation model has been established by cutting 1/4 of the said shell, the medium loads of different weight being transplanted on elements of the shell.

视钢球磨煤机为由端盖与筒体构成的回转体,截取壳体的 1/4 建立有限元计算模型,将不同重量的介质荷载等效移植到壳体单元上,通过有限元计算分析,得到了介质重量变化对钢球磨煤机端盖应力的影响数据。

2.

The welding and restoring work of cracks on the entrance end cover of ЩВ70 / 850 ball mill is summarized in the paper, which can provide some references for other power plants.

通过对 ЩB1 70 / 850型球磨机入口端盖裂纹的焊接修复工作进行总结 ,为电厂同类型磨煤机端盖焊接修复工作提供参考依据。

3.

The article analyzes the problem that the connecting bolts used in QS2736 spill type ball mill\'s end cover break frequently in the dissolution technology of alumina process flow,puts forward the corresponding solution methods and preventive measures.

对氧化铝生产流程中溶出工艺使用的QS-2736溢流型球磨机(溶出磨)端盖法兰连接螺栓出现断裂的问题进行分析,并提出相应的解决方法和预防措施。

4) Cover

[英]['kʌvə(r)] [美]['kʌvɚ]

端盖

1.

An improvement on machining process of cover;

端盖机械加工工艺的改进

2.

The stamping technology and the structure of the die for a relatively complicated and high accuracy connecting cover of the motor were introduced.

介绍了一种形状较复杂、加工精度要求较高的电动机连接端盖的冲压工艺和模具结构,重点阐述了保证零件精度要求的模具结构特点,保证了零件质量,降低了成本,提高了生产效率。

5) end-cover

端盖

1.

The application shows that this jig is suitable for the turning of this kind of parts such as the end-cover of the flange motor.

实际应用表明 ,该夹具对此类零件如凸缘电机端盖具有很好的适用

6) endshield

['end,ʃi:ld]

端盖

1.

Improvement of Rigidness of Endshield to Reduce the Axial Vibration of Motor;

提高端盖刚度降低电机轴向振动

2.

Design on Equipment of Medium-Sized Motor Endshield used in Static Pressure Test

中型电机端盖静压试验工装的设计

3.

the motor is horizontally mounted(IMB3); one fan bowl is provided at top of the motor but YKK motor is provided with one air-to-air cooler;the stator frame welded with steel plates is of international conventional box construction;the bearing is type B/BJ endshield spherical sleeve bearing,VPI process is applied to the stator core with windings; and the frame, stator an.

介绍了Y(YKK) 6 30 6kV、10kV中型高压三相异步电动机的设计特点 :安装方式为卧式IMB3,项部装有一个通风罩 (YKK的为空冷器 ) ,定子机壳为钢板焊接的国际流行箱型结构 ,轴承采用B/BJ型端盖式球面滑动轴承 ,带绕组定子铁心采用了VPI少胶真空压力整浸绝缘工艺 ,机壳、定转子冲片和风扇尽量采用通用

补充资料:封盖落料-拉伸-切边-成形复合模

兰州电机有限责任公司(甘肃兰州 790050) 杨思明

[摘要]分析了封盖零件的成形工艺特点,介绍了此类零件复合冲压模的结构设计。

关键词 封盖 复合模 落料 拉伸

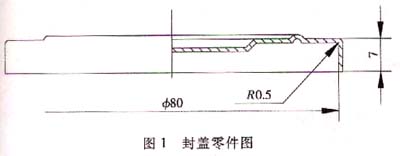

1 零件分析

图1所示为空气滤清器的封盖,生产批量大,材料为08F,料厚0.35mm,外圆直径个80mm,拉伸高度7mm,成形后口部要求无飞边。该零件是一种典型浅盖零件,该封盖原加工工艺为落料--拉伸--压延,造成口部拉伸后有飞边,需人工清除,费力费时。

2 冲压工艺分析

经以上计算,可一次拉伸成形,凸凹模环形壁厚强度完全可以满足要求,采用一次成形工艺为:落料--拉伸--切边--成形。

3 模具结构设计与设计要点

3.1 模具结构及其工作过程

复合棋结构如图3所示。将条料送至凹摸15上,凸凹模12下行,卸料板13压紧条料,凸凹模12与凹模15进行落料,凸凹模12继续下行,落下的圆坏料与已有压边力的压料圈5接触,拉伸凸模6与凸凹模12进行拉伸成形,凸凹模12继续下行,凸模4外圆与凸凹模12内切边模进行切边。凸凹模12再下行,拉伸凸模6与打料板7端面接触,进行压延成形。凸凹模12上行,打料板7在冲床作用下打下成品一次成形结束。

1弹簧 2顶杆 3下模座 4凸模 5压料圈 6拉伸凸模 7打料板 8卸料杆 9上模柄 10打件杆 11上模固定板 12凸凹模 13卸料板 14固定螺栓 15凹模 16下模固定板

3.2 设计要点

(1)落料凹模15内孔D尺寸计算时取最小值,在拉伸过程中试模修配拉伸凸模6圆角半径来确定切飞边量。

(2)拉伸凸模6与凸模4需设计成二个单独体,便于凸模4刃口刃磨,凸模4中心孔设计成螺纹孔便于起模。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条