2) vacuum freeze drying equipment

真空冷冻干燥装置

1.

TH FD 50×2 vacuum freeze drying equipment for food;

TH-FD50×2食品真空冷冻干燥装置

3) freeze drying

冷冻干燥

1.

Influence of freeze drying on cow milk fatty acids and its isomers;

冷冻干燥对牛乳脂肪酸及异构体成分的影响

2.

Study on atmospheric absorbent fluidized freeze drying of solid food;

固态食品常压吸附流化冷冻干燥的研究

3.

Beneficial effects of intracellular trehalose on red blood cells by freeze drying;

载入海藻糖红细胞冷冻干燥保存的实验研究

4) freeze-dried

[英]['fri:zdraid] [美]['friz,draɪd]

冷冻干燥

1.

The isolated strains from kefir grains were freeze-dried, the quality of these freeze-dried procedure were assessed.

对从开菲尔粒子中分离到的菌种进行冷冻干燥,并检测冻干后发酵效果,结果显示,当添加保护剂:10%海藻糖+5%山梨醇+10%甘油+5%低聚异麦芽糖,冷冻干燥条件为-62℃,0。

2.

OBJECTIVE To prepare brevescapine(BRE) inclusion complex freeze-dried powder injection and evaluate its safety.

方法以2-羟丙基-β-环糊精(HP-β-CD)为包合材料,采用冷冻干燥法制备灯盏花素包合物冻干粉针,摩尔连续递变法确定包合物的包合比例,红外光谱法、差示扫描量热法对包合物进行验证,高效液相色谱法测定包合物前后水溶液中药物的溶解度,并考察灯盏花素冻干粉针剂的溶血性和血管刺激性。

3.

Objective To prepare tanshinone ⅡA inclusion complex freeze-dried powder injection and study its characters.

方法以羟丙基-β-环糊精(HP--βCD)为包合材料,采用冷冻干燥法制备注射用丹参酮ⅡA包合物;用差示扫描量热法、红外光谱法及相溶解度法验证包合物的形成;考察注射用丹参酮ⅡA包合物复溶后的pH值、澄清度、渗透压、与稀释剂的配伍稳定性及溶血性等基本性质。

5) freeze-dry

[英]['fri:z,draɪ] [美]['friz,draɪ]

冷冻干燥

1.

The Application of HACCP in Mushroom Made by Freeze-dry Technique;

HACCP在冷冻干燥蘑菇生产中的应用

2.

The application of HACCP system in asparagus made by freeze-dry technique;

HACCP在冷冻干燥芦笋生产中的应用

3.

Freeze-drying Cryoprotectant Optimized by Orthogonal Experiment for Acidithiobacillus ferrooxidans;

正交法优化嗜酸氧化亚铁硫杆菌冷冻干燥保护剂

6) Freeze-drying

[英]['fri:z'drai] [美]['friz'draɪ]

冷冻干燥

1.

Numerical simulation and experimental study of column food in freeze-drying process basis on URIF model;

基于URIF模型的圆柱型物料冷冻干燥过程的二维模拟及验证

2.

Experimental Study on Technological Parameters of Apple Freeze-drying;

苹果冷冻干燥工艺参数的试验研究

3.

Simulation of transport processes and phase distributions during freeze-drying by pore-scale network modeling;

冷冻干燥过程相迁移和相分布的孔尺度网络模型与模拟

补充资料:VFD真空冷冻干燥装置

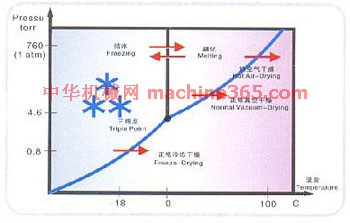

基本原理

真空冷冻干燥是在真空状态下利用冰晶升华的原理,在高真空的环境下,使预先冻结的物料中的水分不经过冰的融化直接从冰态升华为水蒸汽,从而使物料干燥。

真空冷冻干燥产品的特点

可确保食品中蛋白质、维生素等各种营养成分,因而是能最 大限度地保持食品的色、香、味; 由于低温、真空、无液态化、帮能有效地防止干燥过程中营

养成分的转化和状态变化; 冻干制品成海绵状,无干缩,复水性能好,食用方便; 冻干制品含水量很低,相应包装后可常温贮存和运输

该装置可加工多种食品:

蔬菜类:蘑菇、香菜、荷兰豆、香葱、蒜片、玉米等;

水果类:荔枝、香蕉、草莓、菠萝等;

鱼肉类:虾仁、甲鱼、牛肉、猪肉、鸡肉等。

其它类:茶叶、药材、蛋花汤、人参、咖啡等。

----该设备主要由干燥-捕水系统、真空系统、制冷系统、媒体系统、物料传输系统、微机自控系统等组成。

主要技术参数

名称与规格 | VFD-50 | VFD-75 | VFD-100 | VFD-150 | 2×VFD-100 |

有效干燥面积 (平方米) | 50 | 75 | 100 | 150 | 200 |

干燥有效层数 (层) | 18 | ||||

料盘尺寸 (mm) | 540×635×30 | ||||

干燥-捕水器尺寸 | Φ2.4×4.9m | Φ2.4×7.0m | Φ2.4×9.2m | Φ2.4×13.4m | Φ2.4×9.2m |

工作真空 (Pa) | 13.3 - 133 | ||||

干燥板温度 | 室温 - +130℃ | ||||

捕水器工作温度 | -30℃ - +42℃ | ||||

捕水量 (Kg/次) | 500 | 750 | 1000 | 1500 | 2000 |

耗冷量 (KW) | 56 | 84 | 112 | 168 | 207 |

耗汽量 (Kg/h) | 150 | 255 | 300 | 450 | 600 |

装机功率 (KW) | 44 | 58 | 80 | 108 | 115 |

真空冷冻干燥原理

冷冻车间平面示意图

干设备所需建筑面积

| VFD-50 | VFD-75 | VFD-100 | VFD-150 | |

| 冻干+速冻 (平方米) | 180 | 220 | 250 | 320 |

真空冷冻干燥装置工作原理示意简图

浙江省上虞市华丰制冷通风设备厂

电 话:0575-2098888 2091208 传 真:0575-2091218

地 址:浙江省上虞市章镇工业园区 Email:manager@sy-huafeng.com

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条