1) Resins Base Pattern Materials

树脂基模料

2) resin matrix materials

树脂基材料

1.

According to the analysis of the thermal chemical ablative mechanism of resin matrix materials under pyrolytic reaction at elevated temperature, the ablation phase transformation properties and the thermal deformation behavior of the materials were investigated by Eshelby equivalent inclusion method.

通过对树脂基材料高温热解反应过程中热化学烧蚀机理的分析 ,利用细观力学的 Eshelby等效夹杂方法研究了材料高温烧蚀相变特性和热变形行为。

3) alkyd moulding compound

醇酸树脂模塑料

4) Resin matrix composite

树脂基复合材料

1.

The article described mechanism of physical and chemical modification technology of resin matrix composite and its progress.

概述了树脂基复合材料物理及化学改性技术的作用机理,以及近年来改性技术的最新进展情况,对几种典型改性树脂基复合材料做了简要的介绍。

2.

The theory and application of the resin matrix composite in infrared stealthy technique,radar stealthy technique,and multiple spectrum stealthy technique are presented.

阐述了树脂基复合材料在红外隐身,雷达隐身、多谱隐身技术中的隐身原理及应用情况,分析了树脂基复合材料在隐身技术中的地位和广阔应用前景。

3.

The basic conception of the photopolymerization reaction, the constitution of the photopolymerization resin matrix and the kinds of the reinforced materials in the photopolymerization resin matrix composites were introduced.

介绍光固化反应的基本概念、光固化树脂基体的组成及光固化树脂基复合材料用增强材料的种类。

5) resin based composite

树脂基复合材料

1.

The requirements for the interfacial combining of the resin based composite under forced condition have been analyzed.

分析了树脂基复合材料受力状况下对界面结合的要求 ,着重介绍了微量冲击和临界纤维断裂长度分析两种检测树脂基复合材料界面剪切强度的方法及其研究成果。

2.

Several resin based composites were prepared by filling of graphite, carbon black and coke in phenolic resin, NBR modified phenolic resin and polytetrafluroethylene (PTFE) as the bonding agents.

采用酚醛树脂、丁腈橡胶改性酚醛树脂和聚四氟乙烯 (PTFE)作为粘结相 ,通过填充一定配比的石墨、焦炭及碳黑制备了 3种树脂基复合材料电刷试样 ,并在 MM- 2 0 0型摩擦磨损试验机上对比考察了复合材料试样与铜对摩时的摩擦磨损性能 。

3.

The types of resin based absorbing composites were presented,such as carbon/thermoplastic resin based composite,fiber reinforced resin composites,resin based nanocomposite.

本文介绍了目前应用在吸波中的几种新型的树脂基吸波复合材料,如碳/热塑性树脂基复合材料、纤维增强树脂基复合材料、树脂基纳米复合材料。

6) polymer composites

树脂基复合材料

1.

Strength and modulus anisotropy of short fiber reinforced polymer composites;

短纤维增强树脂基复合材料强度和模量的各向异性

2.

As a result of the influence of moisture environments or other severe environments,the mechanical properties of polymer composites will deteriorate with time and make the actual reliability of them lower than that of the pre-designed reliability.

在潮湿环境及其他严酷环境作用下,树脂基复合材料结构的力学性能会逐步降低,使得材料的实际可靠度比预设计的可靠度低。

3.

The influence of low temperature plasma treatments on the chemical and mechanicalproperties of carbon fiber as well as carhon-fiber-reinforced polymer composites are described.

综述了低温等离子体处理对碳纤维(CF)及其增强树脂基复合材料(CFRP)的化学和机械性能的影响,同时也探讨了等离子体技术在纤维复合材料应用中存在的问题和研究方向。

补充资料:封盖落料-拉伸-切边-成形复合模

兰州电机有限责任公司(甘肃兰州 790050) 杨思明

[摘要]分析了封盖零件的成形工艺特点,介绍了此类零件复合冲压模的结构设计。

关键词 封盖 复合模 落料 拉伸

1 零件分析

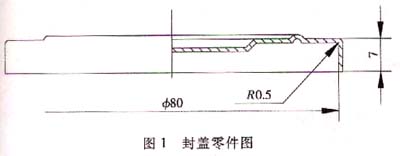

图1所示为空气滤清器的封盖,生产批量大,材料为08F,料厚0.35mm,外圆直径个80mm,拉伸高度7mm,成形后口部要求无飞边。该零件是一种典型浅盖零件,该封盖原加工工艺为落料--拉伸--压延,造成口部拉伸后有飞边,需人工清除,费力费时。

2 冲压工艺分析

经以上计算,可一次拉伸成形,凸凹模环形壁厚强度完全可以满足要求,采用一次成形工艺为:落料--拉伸--切边--成形。

3 模具结构设计与设计要点

3.1 模具结构及其工作过程

复合棋结构如图3所示。将条料送至凹摸15上,凸凹模12下行,卸料板13压紧条料,凸凹模12与凹模15进行落料,凸凹模12继续下行,落下的圆坏料与已有压边力的压料圈5接触,拉伸凸模6与凸凹模12进行拉伸成形,凸凹模12继续下行,凸模4外圆与凸凹模12内切边模进行切边。凸凹模12再下行,拉伸凸模6与打料板7端面接触,进行压延成形。凸凹模12上行,打料板7在冲床作用下打下成品一次成形结束。

1弹簧 2顶杆 3下模座 4凸模 5压料圈 6拉伸凸模 7打料板 8卸料杆 9上模柄 10打件杆 11上模固定板 12凸凹模 13卸料板 14固定螺栓 15凹模 16下模固定板

3.2 设计要点

(1)落料凹模15内孔D尺寸计算时取最小值,在拉伸过程中试模修配拉伸凸模6圆角半径来确定切飞边量。

(2)拉伸凸模6与凸模4需设计成二个单独体,便于凸模4刃口刃磨,凸模4中心孔设计成螺纹孔便于起模。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条