1) magnetic abrasive finishing technology

磁粒光整加工

1.

In order to solve the problem of finishing complex mould surface precisely, combining magnetic abrasive finishing technology with computerized numerical control (CNC) and empoldering three coordinates CNC system suited to magnetic abrasive finishing, the CNC system of open architecture based on the Windows98 is developed.

为解决模具型腔表面高精度光整加工的难题,将磁粒光整加工与数控技术结合起来,以开放式CNC体系为指导思想,在Windows98下开发适合磁粒光整加工的三坐标CNC系统。

2) magnetorheological finishing(MRF)

磁流变光整加工

1.

The machining principles and characteristics of electrolytic in-process dressing(ELID)-grinding and magnetorheological finishing(MRF) were analyzed,and new ultra-precision synergistic finishing process inte-grated with ELID-grinding and MRF was applied to nano-precision finishing for silicon mirror.

分析了在线电解修整(ELID)磨削和磁流变光整加工(MRF)的加工原理与特点,充分结合这2种技术的优点对单晶硅反射镜进行纳米级精度的组合加工。

3) abrasive jet finishing(AJF)

磨粒喷射光整加工

4) magneto-rheological finishing(MRF)

磁流变光整加工(MRF)

5) finishing

[英]['finiʃiŋ] [美]['fɪnɪʃɪŋ]

光整加工

1.

Pulse Electrochemical Finishing with a Shaped Cathode and Its Application on Roller;

成型阴极脉冲电化学光整加工在轧辊上的应用

2.

Material Removal Model for Abrasive Jet Precision Finishing Restricted by Abrasive Wheel;

砂轮约束磨粒喷射精密光整加工材料去除模型

3.

Pulse Electrochemical Finishing with a Shaped Cathode and Its Application;

成形阴极脉冲电化学光整加工技术应用研究

6) finishing machining

光整加工

1.

Experimental Research on Magnetic Abrasive Finishing Machining on Complicated Surface;

自由磨粒复杂曲面磁力研磨光整加工试验研究

2.

Research and Progress on Finishing Machining;

光整加工技术的研究与发展

3.

The elastically micro bladed cutting of magnetic abrasive (MA) is capable of realizing automatic finishing machining of free curved surface.

磁粒的弹性微刃切削可以实现自由曲面的自动化光整加工 ,但制造方法不同 ,磁粒性能也不同 。

补充资料:KZL系列快速整粒机

概述:

本机适用于中西药、食品、化工颜料及饲料等行业中颗粒的破碎及整理。

经各种造粒工艺及设备所得到的颗粒形状及规格各异。将造粒后的颗粒经本机高速刀片组合切割后,经网板排出,便可得到形状及规格基本一致的颗粒。

本机全部零件均采用不锈钢制造,表面抛光、装拆与清洗十分方便。

应用:

干式、湿式颗粒均匀化;整粒团块物料的粉碎、整粒;湿料制粒;热敏性物料粉碎。

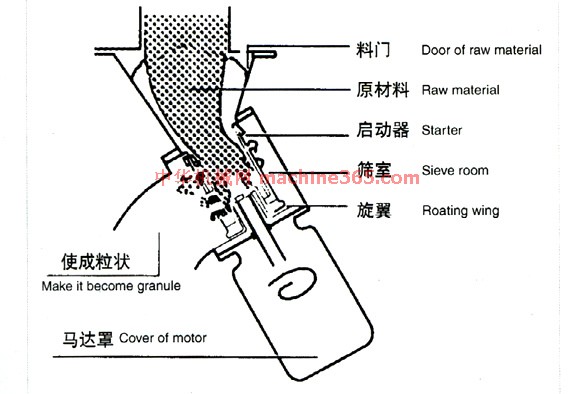

结构简图:

技术参数:

型号 | 100 | 200 | 300 |

定子直径 | 100 | 200 | 300 |

能力 | 20-150 | 100-500 | 500-1500 |

功率 | 0.75 | 1.5 | 5.5 |

转速 | 180-1400 | 175-1400 | 200-1400 |

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条