1) drying shrinkage dynamics

干缩动力学

1.

The drying shrinkage dynamics and drying shrinkage process of high C3S cement mortar were studied according to its drying shrinkage curves tested at two drying condition of RH 50% and RH 40% at 20 ℃.

通过测定高硅酸三钙(C3S)水泥砂浆在20℃两种相对湿度(RH40%,RH50%)下的干缩曲线,研究了该水泥砂浆的干缩动力学及干缩过程,揭示了该水泥砂浆干燥收缩过程的演变规律。

2) shrinkage kinetic

收缩动力学

1.

After compacted with a steel die, the green compact was sintered in hydrogen in order to investigate its shrinkage kinetic curve.

采用催化-凝胶法制备的平均粒径60nm的纳米钨粉为原料,经钢模压制成生坯,用高温膨胀仪测定了纳米钨粉坯体的烧结收缩动力学曲线;然后分别测定了不同烧结温度和烧结时间下烧结体晶粒尺寸和相对密度的变化。

3) drying dynamics

干燥动力学

1.

The drying dynamics models of baked drying and microwave drying were Page equation,and the drying dynamics model of vacuum drying was simplification diffuseness mode.

烘干和微波干燥动力学模型为Page方程;真空干燥为单项扩散模型。

2.

The principles,characters,drying dynamics and the important effect factors of vacuum-microwave drying technology are analyzed in this paper;the applications of the vacuum-microwave drying technology are introduced at the same time.

着重阐述了微波真空组合干燥技术的机理、特点、干燥动力学以及影响微波真空干燥的重要因素,并对微波真空组合干燥的应用研究进行了介绍。

4) drying kinetics

干燥动力学

1.

In accordance with the problems occurred in the existing production process and equipment of styrene butadiene styrene block copolymer (SBS),the drying kinetics for the SBS particle at the outlet of the drying extruder was studied by using weight subtraction method on the single layer cylinder fluidized bed drier.

针对SBS现有生产工艺和设备中存在的问题 ,在单层圆筒形流化床干燥试验装置上 ,采用减重法对SBS生产装置中膨胀干燥机出口处的SBS胶粒进行了干燥动力学的研究。

2.

Drying kinetics experiments of magnesium hydroxide nanorods were carried out, and the drying curves as well as drying rate curves were obtained under different drying medium temperatures of 333K-513K along with the wet material bed -layer thickness of 7mm and different wet material bed -layer thicknesses of 0.

采用热分析动力学技术对干燥动力学实验数据进行处理后,得到氢氧化镁纳米棒的干燥微分机理函数为f(1-MR)=2MR(-MR)1/2,干燥积分机理函数为g(1-MR)=(-lnMR)1/2,干燥方程为MR=exp[-(kt)2],干燥速率方程为-dMR/dt=2kMR(-lnMR)1/2,干燥速率常数为k=Aexp[-Ea/RT]=Aexp[-Ev(1+CLL)/RT];指前因子A=10。

3.

This paper designed minitype laboratory measuring system for drying kinetics, to measure drying kinetics curve and equilibrium data.

针对闭式循环、自动参数检测及数据采集等试验台必备功能,对小型实验室干燥动力学测试系统进行了工艺及装备设计,用于测量干燥动力学曲线和平衡数据。

5) shrinkage kinetic curve

收缩动力学曲线

1.

The densification of nanoscaled W-Cu powder was investigated through measurements of the shrinkage kinetic curves in hot pressing and hydrogen sintering and compared with that of nanoscaled W powder and traditional Cu powder.

以纳米W,Cu粉末为原料,通过测定H2中热压烧结和无压烧结的收缩动力学曲线, 研究了纳米W-40%Cu化学混合粉末的致密化过程。

2.

The effect of pressure, gas atmosphere and W particle size on the shrinkage kinetic curve of nano-scaled W-Cu composite powders during hot pressing were studied.

采用纳米W-Cu合金粉进行热压烧结,研究热压压力、热压气氛、钨粉粒度对热压烧结收缩动力学曲线的影响,观察和测定合金中钨晶粒的长大,测定部分力学性能,实验结果表明,采用纳米W-Cu合金粉在H_2中热压烧结的方法可以在较高压力、很低的烧结温度下制成钨晶粒的超细晶粒W-Cu合金,其相对密度可达98。

3.

The characteristics of swell-shrinkage kinetic curve during sintering the compact of W-Ni- Fe 10% with primary mean grain size less than 200 nm in hydrogen atmosphere was researched by high tem- perature dilatometer.

利用高温膨胀仪在氢气气氛下测定和研究了粉末平均晶粒≤150nm的W-(Ni-Fe) 10%合金在烧结过程中的膨胀─收缩动力学曲线特征、起始收缩温度、剧烈收缩温度、收缩速 率与W粉的平均粒径、烧结温度、升温速度以及压坯密度的关系。

6) copolycomdensation kinetics

共缩聚动力学

补充资料:动力机械:内燃机动力学

研究内燃机运转中的力学现象的科学。其主要任务是研究分析内燃机运转时各主要零件的运动规律及其受力情况﹐用以作为内燃机零件设计﹑计算的依据。它还研究这些力对内燃机动力装置的影响及其消减方法。内燃机动力学的主要内容为曲柄连杆机构运动学﹑曲柄连杆机构动力学和内燃机平衡分析等。

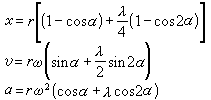

曲柄连杆机构运动学 研究曲柄﹑连杆﹐尤其是活塞的运动规律。活塞作周期性往复运动时的位移 、速度

、速度 和加速度

和加速度 可用下述各式近似求算

可用下述各式近似求算

式中 为曲轴转角﹔

为曲轴转角﹔  为曲轴旋转角速度﹔

为曲轴旋转角速度﹔ 为曲柄半径﹔

为曲柄半径﹔ 为曲柄半径

为曲柄半径 与连杆长度

与连杆长度 之比﹐即

之比﹐即  =

=  /

/

曲柄作回转运动﹐连杆作复杂的平面运动。连杆的运动往往被简化分解为随活塞组的往复运动和随同曲柄的旋转运动。

曲柄连杆机构动力学 研究分析曲柄连杆机构(见曲柄滑块机构)在运动中力的生成﹑传递和输出。作用在曲柄连杆机构上的力有曲柄连杆机构运动时产生的往复惯性力和离心惯性力﹐以及内燃机气缸内的气体压力。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条