1) diametrical dimension error

径向尺寸误差

2) diameter error

尺寸误差

1.

To explore the mechanism of the follower rest,a united model is developed to simulate the formation of the diameter error of the slender bar.

为探索跟刀架的作用机理,开发了一个联合模型用以仿真细长轴车削尺寸误差的形成过程。

3) Size error

尺寸误差

1.

The influence of installing height of CNC lathe tool on radical size error;

数控车床车刀的安装高度对径向尺寸误差的影响

2.

Pump wheel base uses water blast purged sand technology later and produces big size error and shape error.

泵轮毛坯应用水爆清沙技术,产生较大的尺寸误差和形状误差,通过查找产生误差的原因,经多项工序实验和工艺探讨,不仅减少了损失,也闯出了一条保证整机质量的。

4) dimensional error

尺寸误差

1.

To optimize the turning process,artificial neural network was employed to investigate dimensional error during slender bar turning with movable support in this work.

为优化细长轴车削加工,应用人工神经网络方法建立使用跟刀架车削细长轴时的加工尺寸误差预测模型,并基于获得的预测模型研究切削用量对尺寸误差的影响。

2.

The mathematical model of fitted type spherical hydrostatic bearing with consideration of the dimensional error is established, and the effect of the dimensional error on the characteristics of the bearing is studied in detail by means of simulation, then the regularity of the effect is clarified, and valuable suggestion of design is put forward.

建立了考虑尺寸误差作用的配合型静压球轴承的数学模型,研究了尺寸误差对于球轴承性能的影响,并得到其影响规律,最后提出一些有价值的设计建议。

5) Dimension Error

尺寸误差

1.

Effect of Amplitude during Precision Ultrasonic Vibration Cutting upon Machining Dimension Error of Workpiece;

超声振动精密切削振幅对工件尺寸误差的影响

2.

The part error with RPT is classified as dimension error, shaped error and roughness of surface.

快速成型制件的的误差分为尺寸误差、形状误差和表面粗糙度。

3.

The dimension error is computed and presented.

对同济大学土木工程防灾国家重点实验室的六个振动台试验模型进行测量,得到了大量试验模型尺寸误差数据。

6) radial error

径向误差

1.

To meet the requirement of 100% on-line inspection of gears in mass production in automotive and motorcycle industry, the two-flank principle is used to check the gear radial errors(thickness, radial composite error, run-out and error burs)and the gear axial errors(mean helix error, helix error and taper error)to realize the quick on-line inspection of gear machining flaws.

针对汽车、摩托车齿轮生产企业大批量齿轮生产现场,实现在线100%快速检测需要,本项目采用双面啮合原理测量齿轮的径向误差(齿厚、径向综合偏差、径向跳动、毛刺等)和轴向误差(平均齿向偏差、齿向偏差、锥度误差),实现齿轮的制造缺陷的现场快速检测。

2.

This paper analyzes the reason for radial error and tangential error in the course of gears rolling.

分析了滚齿过程中,齿轮的径向误差和切向误差产生的原因,径向误差是指滚齿时出现几何偏心,使所切齿轮的轮齿发生径向位移而引起的齿轮累积误差,切向误差,是由于机床的工作台不等速旋转,使所切齿的轮齿沿切间发生位移所引起的齿距累积误差,两种误差产生的原因不一样,但对齿轮传动的精度有很大的影响。

3.

The paper analyzes the reason of track shape error and the phenomenon of radial error propagation.

本文分析了自伺服过程中产生轨道形状偏差的原因及其带来的径向误差传递现象。

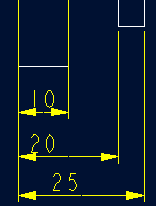

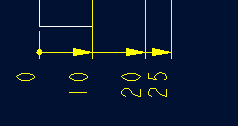

补充资料:工程图标准尺寸及坐标尺寸

标准标注类型,是我们常用的标注类型。而坐标标注是便于数控加工采用的另一中标注形式。PRO/E可以将两种标注方式进行转换。

· 3.2 标准标注到坐标标注的转换

注意: 转化为坐标标注的尺寸必须是线性标注的,下列尺寸不能转化为坐标标注:

- 被显示成线性尺寸的直径

- 中心线尺寸

- 选择MODIFY DRAW > Dim Params > Dim Type > Ordinate Dim > Create Base.

- 选择作为参考基准线的尺寸

- 选择基准的引出线,该点为0点

- 选择 MOD DIM TYPE > Lin to Ord .

- 选择线性尺寸:注意:必须选择具有相同基准的尺寸

========>>>>

========>>>>

1. 选择 DIM PARAMS > Diam Dim Type .

2.点击Ord to Lin

3.选择尺寸即可

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条