1) friction welding technology

摩擦焊接工艺

1.

Based on friction welding technology optimized by this study,it is fact that welding of 100%,fine microstructure and morphology in the welding condition,coefficient of strength to be well in a welding zone and higher coaxial accuracy of joint welded were obtained to the superalloy Monel K500.

在本文所优化的摩擦焊接工艺条件下MonelK500合金均可获得焊区100%焊合、焊态组织结构良好、焊合区强度系数满足要求、焊件同轴度精度较高的摩擦焊接头。

2.

Based on friction welding technology optimized by this study,it is fact that welding of 100,fine microstructure and morphology in the welding condition,coefficient of strength to be well in a welding zone and higher coaxial accuracy of joint welded were obtained to the superalloy Inconel 62

研究与评定了Inconel625镍基高温合金的摩擦焊接性能,在本文所优化的摩擦焊接工艺条件下,Inconel625合金均可获得焊区100%焊合、焊态组织结构良好、焊合区强度系数满足要求、焊件同轴度精度较高的摩擦焊接头。

2) Friction butt-welding process

摩擦对焊工艺

3) friction welding

摩擦焊接

1.

Analysis gauses for crack formation on friction welding joint for ring skeleton;

线圈骨架摩擦焊接头裂纹形成的原因分析

2.

A model of artificial neural network for optimizing technological parameter of friction welding of dissimilar material;

优化异种材料摩擦焊接工艺参数的神经网络模型

3.

3-D numerical simulation of continuous-drive friction welding process of GH4169 alloy;

GH4169合金连续驱动摩擦焊接过程三维数值模拟

4) Rubbing process

摩擦工艺

5) Friction welding technique and equipment

摩擦焊工艺及设备

6) Friction welded joint

摩擦焊接头

1.

Effect of external electric field on diffusion behavior of copper andstainless steel friction welded joint during post weld annealing treat-ment;

电场热处理的铜与不锈钢摩擦焊接头扩散行为

2.

Failure analysis of friction welded joint of hollow sucker rod;

空心抽油杆摩擦焊接头断裂失效分析

3.

Based on reliability theory,the specification of accelerate life test for friction welded joints in boiler snake pipe was worked out.

通过对大量新制的 15CrMo摩擦焊接头的高温内压爆破持久试验 ,证明了试验规范的正确性和各组合应力水平的失效机理的一致性。

补充资料:焊接:摩擦焊

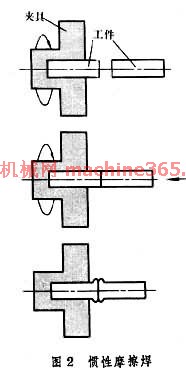

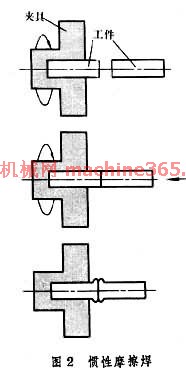

利用工件端面相互摩擦產生的热量使之达到塑性状态﹐然后顶锻完成焊接的方法。车削工件时切屑往往牢牢地黏在刀头上﹐轴与轴瓦之间润滑不良时也会產生局部焊合﹐摩擦焊就是从这些现象出发而发明的。摩擦焊可分为连续驱动摩擦焊和惯性摩擦焊两种。①连续驱动摩擦焊﹕由电动机带动一个工件旋转﹐同时把另一工件压向旋转工件﹐使其接触面相互摩擦產生热量和一定塑性变形﹐然后停止旋转﹐同时施加顶锻压力完成焊接(图1 连续驱动摩擦焊 )。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊 )。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊

)。焊接质量与转速﹑摩擦时间﹑摩擦压力﹑顶锻压力和工件顶锻变形量有关。②惯性摩擦焊﹕由电动机驱动飞轮达到要求的转速﹐然后把一个工件压向夹持在飞轮轴上的转动工件﹐工件间的摩擦阻力使飞轮减速﹐并将飞轮的动能转换成焊接所需的热能(图2 惯性摩擦焊 )。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

)。焊接质量与飞轮惯性矩﹑转速和顶锻力有关。摩擦焊所用的摩擦焊机包括驱动系统(惯性摩擦焊机还包括飞轮)和加压装置。全自动焊机还有上﹑下料装置﹑去飞边装置和参数自动监控系统。摩擦焊适合於焊接杆件和管件﹐工艺简单﹑质量好﹐劳动条件好﹐生產率高﹐耗电量少﹐易於机械化和自动化。摩擦焊在工厂生產线上广泛用於发动机燃烧室﹑排气阀﹑轴﹑轴套﹑杆件﹑管子与法兰﹑石油钻杆和钻芯的连接和变截面杆件的连接。接头焊后不会產生金属间化合物。摩擦焊也常用於异种金属焊接﹐如铝与铜﹑钢﹑镍﹑镁合金﹔铜与钢﹑银等。摩擦焊在铝-铜导线过渡接头的焊接方面应用尤广。惯性摩擦焊也可焊接直径为 100毫米的棒材或截面积为60厘米2的管件。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条