1) cage roll forming

排辊成型

1.

The cage roll forming process of plate is quite complicated, which was simulated by means of a large-scale and nonlinear finite-element analysis software Marc.

通过采用大型非线性有限元软件Marc对板料的排辊成型过程进行了模拟,获得了板带各机架截面处和沿板带纵向的等效应力分布规律。

2.

The cage roll forming process of ERW straight-welded pipes is quite complicated,which is simulated by means of a large-scale and nonlinear finite-element analysis software Marc.

采用大型非线性有限元软件Marc对ERW直缝焊管的排辊成型过程进行了模拟,获得了管坯各截面形状和管坯应变场分布。

2) cage forming

排辊成型

1.

The principle and technics of the Hi-quality forming ways of HFW welded pipe,cage forming and FFX forming,are introduced and analyzed,while the advantages and disadvantages of the two forming ways are compared.

详细介绍了国内外大中直径HFW焊管发展现状,就高品质HFW焊管成型方式排辊成型(cage form ing)和FFX(flexible form ing excellent)成型的成型原理及工艺作了较为详细的介绍及分析,对二者的优缺点进行了对比分析。

3) cage-roll forming technology

排辊成型技术

1.

It introduces three stages of forming technology for high frequency welded pipe as per time period and the development of forming method,namely,roller forming technology in earlier period,cage-roll forming technology in the late of 20th century 60's,and FFX forming technology in the late 20th century 90's,and also describes developing process,advantage and disadvantage of all forming technology.

介绍了高频焊管成型技术按时间段和成型方式发展的三个阶段,即早期的辊式成型技术、20世纪60年代后期的排辊成型技术和90年代后期的FFX成型技术。

4) cage roll forming

排辊成形

1.

Numerical simulation of cage roll forming of ERW pipe based on mixed hardening model;

基于混合硬化模型的ERW焊管排辊成形数值模拟

5) roll forming

辊弯成型

1.

Numerical simulation of multi-pass roll forming of channel section with outer edge;

外卷边槽钢多道次辊弯成型数值模拟

2.

Study on dynamic simulation of roll forming of ERW pipes;

ERW焊管辊弯成型过程的动态仿真研究

3.

Simulation the Roll Forming Process of AHSS;

先进高强度钢辊弯成型有限元仿真研究

6) roll extrusion forming

辊挤成型

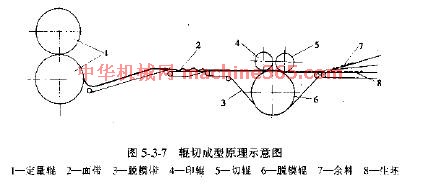

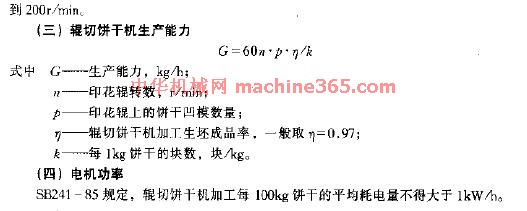

补充资料:辊切式饼干成型机

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条