1) C-scan

C扫描

1.

Realization of Small Sized Tube Ultrasonic C-scan Data Processing Software;

小径管超声C扫描数据处理软件的实现

2.

The quality of TiAl and 40Cr diffusion welding interface was inspected by ultrasonic C-scan method and the relationships between mean and standard deviation of amplitude of interface echo and shear strength were studied.

采用超声C扫描法对TiAl和40Cr扩散焊界面进行了检测,分别研究了界面回波幅度平均值和标准差与接头抗剪强度之间的关系,并讨论了焊接温度和试样表面粗糙度对上述关系的影响及界面气隙长度与回波幅度的关系。

3.

The system could test the inside of switch gears without destroying to provide high quality C-scan image,and evaluated the image after scan.

针对触头焊接质量检测研制的JTUIS-Ⅳ超声无损检测系统,借助现代精密数控、数字信号处理及图像处理技术,通过超声回波探测触头内部结构,进行高质量C扫描成像。

2) C scan

C扫描

1.

The Establishment of Ultrasonic C scan System and Program Development;

超声波C扫描系统研制及其关键技术

2.

The paper designs a scanning unit for immersion ultrasonic C scan system,in which the designing mechanism and structure are illuminated in detail,and indicates that the key factor for precision is the error of the lead screw.

设计了一种超声C扫描检测系统扫描机构,详细介绍了该扫描机构的设计原理及结构实现,并对该机构的定位精度进行了分析,指出在该机构中,影响定位精度的关键因素是丝杠的误差。

3) C-scan

C-扫描

1.

Ultrasonic nondestructive testing for composite materials Ⅱ. noncontant ultrasonic C-Scan techniques;

复合材料的超声检测技术 Ⅱ.非接触超声C-扫描技术

4) C/A scan

C/A扫描

1.

Ultrasonic C/A scan image technique for NDT of small diameter tubes of utility boilers;

电厂锅炉小径管的超声波C/A扫描成像技术

5) C-scan

C型扫描

6) ultrasonic C-scan

超声C扫描

1.

Research on ultrasonic C-scan technique for large unsymmetric composite component;

大型非对称复合材料构件超声C扫描技术研究

2.

An electron beam weld with complex geometrical structure was tested by using ultrasonic C-scan and a simulating testing piece was used in order to simplify experimental condition.

采用超声C扫描成像方法检测了复杂结构电子束焊缝。

3.

By using water immersion focusing method in an ultrasonic C-scan inspection system,the quality of Cu/steel surfacing weld was evaluated.

采用水浸聚焦超声C扫描成像的检测方法,研究了铜钢堆焊接头的质量评价。

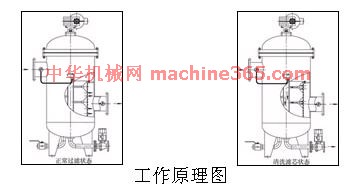

补充资料:<二>JSD系列吸吮扫描式自洁式过滤器

| 一、功能与用途 JSD系列吸吮扫描式自洁式过滤器适用于过滤悬浮状细微杂质,杂质颗粒一般500-25微米,是一种细过滤装置。  二、设备结构与工作原理 JSD系列吸吮扫描式自洁式过滤器采用高强度的Johnson楔形滤网,通过压差控制、定时控制自动清洗滤网。当过滤器内杂质积聚在滤网表面引起进出口压差增大到预定数值时,或定时器达到设定时间时,电动控制箱发出信号,使旋转的吸吮装置开始转动,同时排污阀打开。此时系统泄压排水,在吸嘴与滤网内侧接触部分出现一个相对压力低于滤网外侧水压的负压区,迫使部分净循环水从滤网外侧流入吸嘴内部,吸附在滤网上杂质微粒随水流进入吸嘴内并从排污阀排出。特殊设计的Johnson网使得滤网在吸嘴口产生了喷射效果,任何杂质都将被从光滑的内壁上吸走。整个清洗过程大约只需30-50秒,其间不会断流,清洗耗水量少。 三、主要技术参数

四、结构形式及外形尺寸  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条