1) welding supervision

焊接监督

1.

By introducing the developing situation of ultra supercritical power unit,describing the property and use of new heat resistant steels,and analyzing,analyzing the welding difficulty of new ferric and austenite steel,this paper presents the demands for welding supervision of new heat resistant steels with the consideration of weldability.

介绍了超超临界机组的发展概况,简述了机组中采用的几种新型耐热钢的性能和用途,分析了铁素体耐热钢和奥氏体耐热钢在焊接过程中存在的问题,结合新型耐热钢的焊接性,提出了新型耐热钢焊接监督的要求。

2) weld

焊接

1.

Research on the welding performance of low-carbon nickel;

低碳镍材料焊接性能的研究

2.

Weld Repair and Maintenance of the Steel Belts in the Rotary Belt Condensation Granulators;

回转带式冷凝造粒机钢带的焊接修复与维护

3.

Cause Analysis of the Weld Flaw Between the Flanges and Internal Sleeves of the High Pressure Heat Exchangers and Countermeasures;

高压换热器法兰与内套焊接裂纹原因分析与对策

3) Welding

焊接

1.

The Research Development of Finite Element Simulation in Welding Joint;

焊接接头有限元模拟的研究进展

2.

On Welding of Stainless Steel Compound Plate 16MnR+00Cr19Ni10;

16MnR+00Cr19Ni10不锈钢复合钢板的焊接

3.

Heat source model for 2D welding temperature field simulation based on the configuration of welding line;

基于焊缝形状的二维焊接温度场模拟热源模型

4) jointing

焊接

1.

Application of ultrasonic jointing principle in needle destruction device;

超声波焊接原理在注射针头销毁器中的应用

2.

Quality control in the process of assembling and jointing have interrupted francis turbine at Lijiaxia Hydropower Station;

李家峡水电站混流式水轮机分瓣转轮组合与焊接过程中的质量控制

3.

This paper introduces the jointing method to recover the crushing equipment cone crusher whose axes are broken in two parts.

介绍了大型破碎设备圆锥破碎机主轴断裂后的焊接修复方法。

5) Welded joint

焊接

1.

Prediction system of CTOD for high strength pipeline steel welded joint based on back propagation artificial neural network;

基于BP人工神经网络的高强度管线钢焊接接头性能参数CTOD预测系统

2.

Corrosion characteristics of welded joints of copper pipe in seawater;

紫铜海水管焊接部位在海水中的腐蚀特征

3.

Corrosion behavior of welded joints of copper pipe in artificial seawater;

紫铜海水管焊接部位在人工海水中的腐蚀行为

6) soldering

焊接

1.

Optimized Soldering Process Research on Semi-rigid Cable Modules;

半刚电缆组件焊接工艺优化研究

2.

The Soldering Research for 0.5 mm Pitch CSP;

0.5mm间距CSP焊接工艺研究

3.

Discussion of Soldering Technology for Mix-assembled Circuit Board;

混装电路板焊接工艺技术探讨

参考词条

补充资料:Solid Edge焊接设计

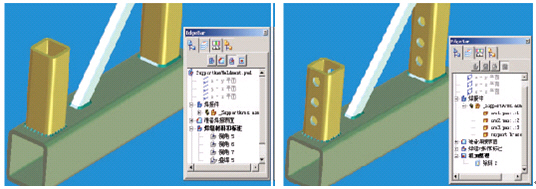

Solid Edge在装配环境中还提供一套专用命令用于焊接件的设计。焊接是在装配环境中在指定焊接件上设计焊缝、表面处理、焊接标注和焊后加工处理等。Solid Edge的制图模块可产生焊前和焊后视图,从而完整表达焊接工序。

专业焊接设计工具

装配环境中的装配特征功能,能提供各种的材料处理的能力,如:材料去除、倒角、旋转拉伸、放样拉伸、打孔等,满足焊前表面预处理、添加焊料到焊后机加工等。用户可以采用和零件设计中一样的设计方法,去完成各种各样的操作,而无需学习新的操作命令。与加工过程一致的控制界面既便于学习,又提高了设计效率。

焊前预处理

使用装配特征提供的诸如倒角、开孔、除料等命令对施行焊接的构件表面进行材料去除的操作,该类操作行业上称之为焊前处理,如采用各种手段打坡口等。

添加焊筋

在焊接处可以添加焊料以反映焊接后机件的真实状况。也可以对焊缝进行标注,以便在生成工程图时直接引用。Solid Edge可以提供自动角焊、坡口焊、跳焊等方法,同时也可以利用Solis Edge提供的多种材料添加功能,用手工的方法定义各种类型的特殊形状的焊筋。

焊后机加工

焊接件完成以后,可以对焊接件进行开孔等机加工。此时添加的特征不会对原来的零件产生影响。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。